Glass is a canvas for printing breathtaking works of art, promotional masterpieces, architectural signage, or industrial labeling. At Boston Industrial Solutions, Inc., we understand the needs and desire of end users to incorporate glass into their lives. From elegant custom drinkware to personalized, unforgettable gifts, printing on glass helps unlock the potential of glass. To achieve stunning prints on glass, we need special techniques and materials to achieve permanent, high-quality prints. Let’s review the best ways to print on glass.

Questions to consider before deciding the best printing method and printer for your needs.

There are various factors to consider before deciding what printing method and equipment to use for glass. Let’s review some of the questions to ensure you select the best printing method for your specific glass printing needs.

- What type of glass product: determining the best printing method starts with you deciding the type of glass products that you will want to print on. For round glass objects, there are candles, shot glasses, mugs, pint glasses, mason jars, wine glasses, spirit bottles, and growlers. For flat items such as glass walls, architectural decorations, etc.

- The desired print quality: deciding the print quality and the objective of the prints; for example, do you want to print a single color, two colors, or full color prints? If you are going to digitally print on glass, you must also decide if you want the artwork to be on one side or a complete wraparound.

- The print size: do you need to print a small, medium, or large glass surface? The size of the print will influence the type of printer to use.

- The printing volume will determine what type of printer to use. Does the artwork change, or will you repeat the same artwork many times?

- Durability is another key factor to consider. Do your prints need to withstand wear, exposure to moisture, or chemicals?

- budget for the printer and maintenance costs associated with running the printing equipment. It is important to consider both initial investment and ongoing operation costs.

Methods for printing on glass

Before choosing a method for decorating glass, it is important to evaluate the questions above. In addition to having some knowledge of the different processes, equipment, and supplies you’ll be working with, it is important to consider the object (parts) you’ll be printing on, your design objectives, volume, and production requirements. With that in mind, let’s review the specialized equipment, techniques, and methods to print on glass.

Digital, Screen and pad printing options

Silk screen printing (screen printing) is a printing process for transferring ink onto a substrate through a mesh, except in blocked areas with a stencil. This is an excellent method for printing 1- or 2- color designs. It is easy to print flat, round, and conical objects. While multi color printing is possible especially with UV screen printing inks, the set-up time and equipment are expensive. Also, screen printing produces a seam when printing 360-degrees. Opacity is of the advantages of silk screen printing. Learn more about our Volta Cylinder Screen Printing Machines.

Pad printing is an excellent process for printing high-volume production runs. Like screen printing, this method is limited by variable data. And like screen printing, pad printing is a good method for printing one or two colors. Four-color process printing is possible with four-color pad printing machines. Industrial marking and simple promotional products such as shot glasses and mugs are excellent applications for pad printing. The major advantages of pad printing include clear, high-resolution, easily repeatable images for high-volume production runs. This method works great for printing on 3D surfaces or unusually shaped objects with irregular surfaces.

Pad printing is an excellent process for printing high-volume production runs. Like screen printing, this method is limited by variable data. And like screen printing, pad printing is a good method for printing one or two colors. Four-color process printing is possible with four-color pad printing machines. Industrial marking and simple promotional products such as shot glasses and mugs are excellent applications for pad printing. The major advantages of pad printing include clear, high-resolution, easily repeatable images for high-volume production runs. This method works great for printing on 3D surfaces or unusually shaped objects with irregular surfaces.

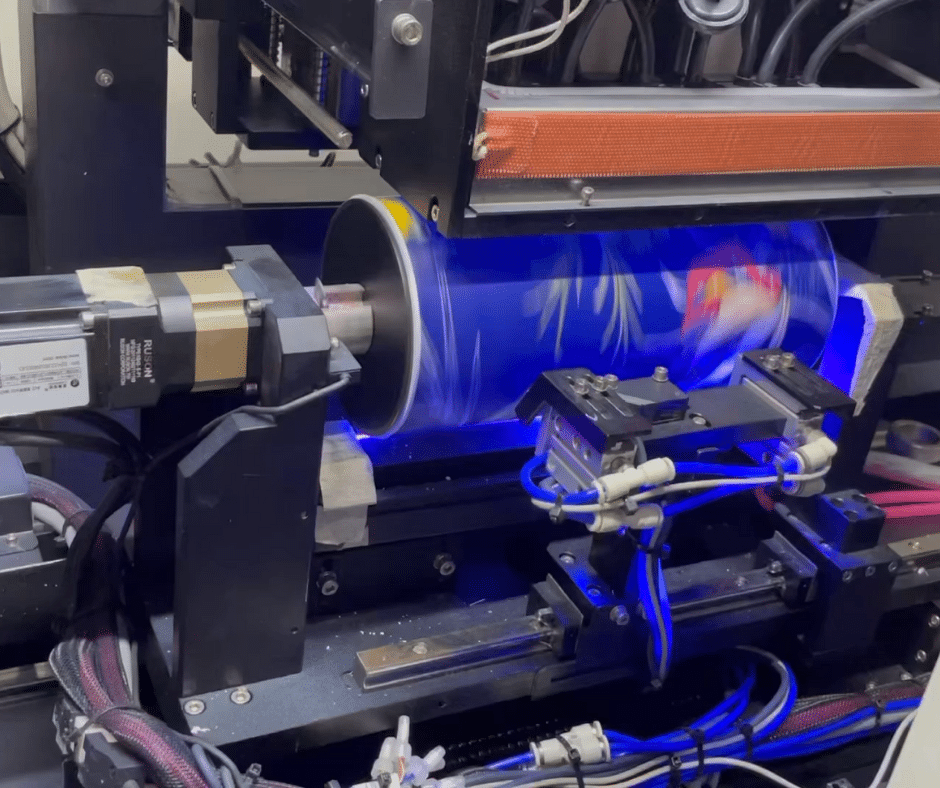

Digital printing utilizes UV printers to deliver impeccable prints on glassware. This printing method is excellent for UV-printed glass wall art, cylindrical drinkware, etc. One of the greatest advantages of cylindrical digital printing on glassware is the ability to reproduce full-color, seamless full-wrap graphics. With UV flatbed printers, it is possible to produce full photographic color prints. UV printing on glass, however, requires pre-treatment such as the Natron® G1 UV ink adhesion promoter. A drawback of printing with UV is the durability of the prints compared to both pad- and screen-printing methods. Our Volta Gyra UV Cylindrical Inkjet Printers come standard with an automatic load-and-unload robotic arm and a conveyor for streamlined production.

UV adhesion promoters, primers, and pre-treatment options

UV Adhesion Promoter improves ink adhesion on low-surface-energy substrates such as glass, ceramic, acrylic, rubber, or metal. To achieve permanent printing on glass, irrespective of the printing method, clean the glass substrate and apply adhesion promoters. This will enhance the durability of the prints.

The best inks for printing on glass

There are several different types of inks developed specifically for printing on glass. Below, we will explore the best available inks in the world today for printing on glass.

The Natron® 314 Series UV inkjet ink for glass is a neutral ink formulate for use with any UV printer using Ricoh gen 4, gen 5 print heads. The ink paired with our inkjet primers, such as G1 glass primer, produces a longer lasting adhesion. This UV ink series works well for both flat and cylindrical glass objects, either in a UV flatbed printer or in a rotary inkjet printer.

The Natron® 270 Series UV ink is also an excellent ink for glass. This is a hard UV ink. Use this ink to print on any hard (rigid) substrate. Use this ink to print on both cylindrical and flat objects.

Screen and pad printing inks

The MG Series ink is for screen and pad printing glass, metals, hard plastics, and tiles. The printed results have a very high gloss, excellent adhesion, and are dishwasher-safe once cured. This is simply the best screen-printing ink for glass.

Printing equipment for glass

There are several printer options Boston Industrial Solutions has for printing on glass, both analog and digital. All our machines are capable of printing on glass. There are several advantages to digital printing over screen or pad printing. Glassware printed digitally requires no drying time, allowing for instant packing and shipping.

UV digital printer machines

The Volta Gyra® Cylindrical Inkjet Printer offers high-quality, high-output printing on glass. This machine can print on demand and has a wide range of allowances, with the ability to print 1.5” to 5.2” containers. With this machine, it is possible to print shot glasses, bear packaging, and many other glass applications.

Pad printers

The print quality and output production for all pad printing machines are the same across all our Volta M series lines. The major differences lie in product height, ink cup size, and print image size.

The M100 is a one-color benchtop pad printer for glass items such as shot glasses. The M100 pad printer features a 100mm ink cup that can print images up to 4” in diameter. Due to the nature of pad printers in general, the silicone pad printing pad will conform to the surface of the glassware. Note that it is not possible to print 360 degrees with a pad printer.

Like the M100, the M2150 2-color pad printing machine is perfect for printing up to 4” in diameter on a drinkware glass. This pad printing equipment adds the ability to print a one- or two-color logo up to 4” in diameter. Choosing a pad printer for glassware allows flexibility in printing other products such as pens, silicone wristbands, and apparel.

How we can help

When printing on glass, it’s essential to choose the method that best suits your project, consider the durability requirements, and select the appropriate inks or materials. Additionally, some methods may require additional steps, such as curing or firing, to ensure the print is permanent and resistant to wear and tear.

At Boston Industrial Solutions, Inc., we understand the challenges that come with printing on glass. We have solutions to help customers easily print on glass. With our glass UV adhesion promoters, it is possible to digitally print on glass with UV inks. We have specifically formulated digital UV-curable inks, pad printing inks, and primers for printing on glassware. The G1 primer for glass helps promote UV ink adhesion to glass substrates and increase abrasion resistance. For analog printing, our series is excellent for screen and pad printing on glass. And lastly, all our pad printing machines are excellent glassware printers. Also, our UV printers, such as the Gyra®, are designed to print both straight-walled and tapered cylinders. All these coupled with our excellent customer service will help you elevate your printing game.