M74F UV METAL ADHESION PROMOTER FOR METALS AND ACRYLICS

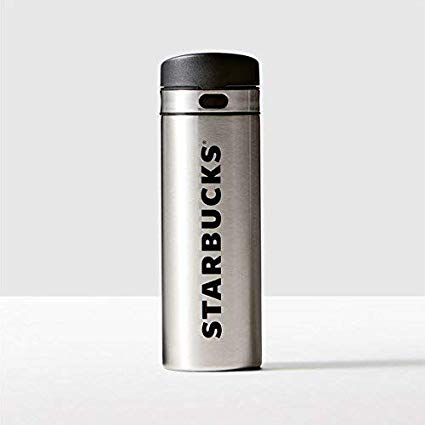

Natron M74F UV ink adhesion promoter for metal printing improves UV ink adhesion on all steel and coated metal items. Also, the M74F is an excellent Adhesion Promoter for acrylic. This metal adhesion primer strengthens the bond between UV ink and the metal substrate, primarily stainless steel. Once cured, this stainless-steel primer drastically improves the bonding and durability of UV prints made on metal. Click here to technical data sheet.

M74F Adhesion Primer guarantees excellent UV ink adhesion on metal parts—both coated and uncoated. The M74F metal adhesion primer is compatible with all OEM UV and LED inkjet inks.

Additionally, this steel primer has a surface molecular activator which scientifically transforms the surface structure of stainless steel and coated metal surfaces to enable permanent bonding. Want to learn more about adhesion promoters, please click here.

What makes stainless steel impossible to print?

Stainless steel is an extremely difficult material to print on using UV inks and LED inkjet inks due to its very smooth surface. In addition, the manufacturing of stainless steel and coated metals involves adding chromium, which creates self-healing properties in metals in the presence of oxygen. As a result, this characteristic reduces the metal’s surface energy.

The lower surface energy makes printing on stainless steel virtually impossible with UV-based inks. For this reason, it is important to use this stainless steel primer when printing on metal substrates.

Can I UV print on metal?

Yes. UV printing has been used for marking metal for some time. To achieve permanent UV ink adhesion on stainless steel, you would need a steel primer for metal—the M74F stainless steel primer. A UV ink primer (UV ink adhesion promoter) is a coating applied to a substrate before printing with UV-curable inks. UV ink primer is typically used on non-porous surfaces such as plastic, metal, and glass. It is used with a wide range of UV-curable inks, including solvent-based, water-based, and 100% solid inks.

Lastly, read more about Pretreatment methods, follow us on Instagram and Visit our YouTube channel for the latest info about printing.

UV printing on acrylic materials

UV printing on acrylic offers more accuracy and significantly more color options than silk screening and pad printing on acrylic. Acrylic (polymethyl methacrylate (PMMA)) is a versatile and durable material that is widely used in various applications. You will find this material in signs, displays, art pieces, and awards. To achieve vibrant, long-lasting prints on acrylic, use the M74FUV Acrylic Adhesion Promoter. The M74F is the best adhesion promoter for acrylic.