UV ADHESION PROMOTER FOR PLASTICS

Natron® PP3 inkjet primer for plastics is a special primer formulated to guarantee printing ink adhesion on difficult-to-print low surface energy plastics such as polypropylene (PP), polyethylene (PE), Polyacetal (POM), Nylon, EPT rubber, acetal, EVA (ethylene vinyl acetate) and powder-coated substrates. PP3 is an adhesion promoter, anti-static agent, and cleaner designed for use with UV and LED curable inks on plastic substrates.

Both Polypropylene and Polyethylene are common plastics that have low surface energy making them impossible for great ink adhesion. This plastic primer increases the plastics surface energy, which in turn improves the ink-substrate bond.

270 Hard and 314 Series UV and LED curable inkjet inks are ideal for printing on plastics. However, there are some plastics that are more challenging than others. These are low energy plastics according to finecal article “How to Bond Low Surface Energy (LSE) Plastics.” This low surface energy property inhibits an ink’s ability to properly ‘wet out’ or bond to the plastic surface. This of course causes problems with many plastic inks leading to weak adhesion or failure of the ink to adhere at all onto the plastic substrate. For this reason, you need Natron™ pp3 inkjet primer for plastics.

To learn more about plastics check out this video by National Geographic.

Characteristics of Low surface energy plastics, or LSE plastics

They are generally glossy, smooth and have a low melting point so they’re easy to process, even at high volumes, and they’re low-density, which helps with light-weighting. Because low surface energy is the primary characteristic of this group, they’re all more difficult to bond.

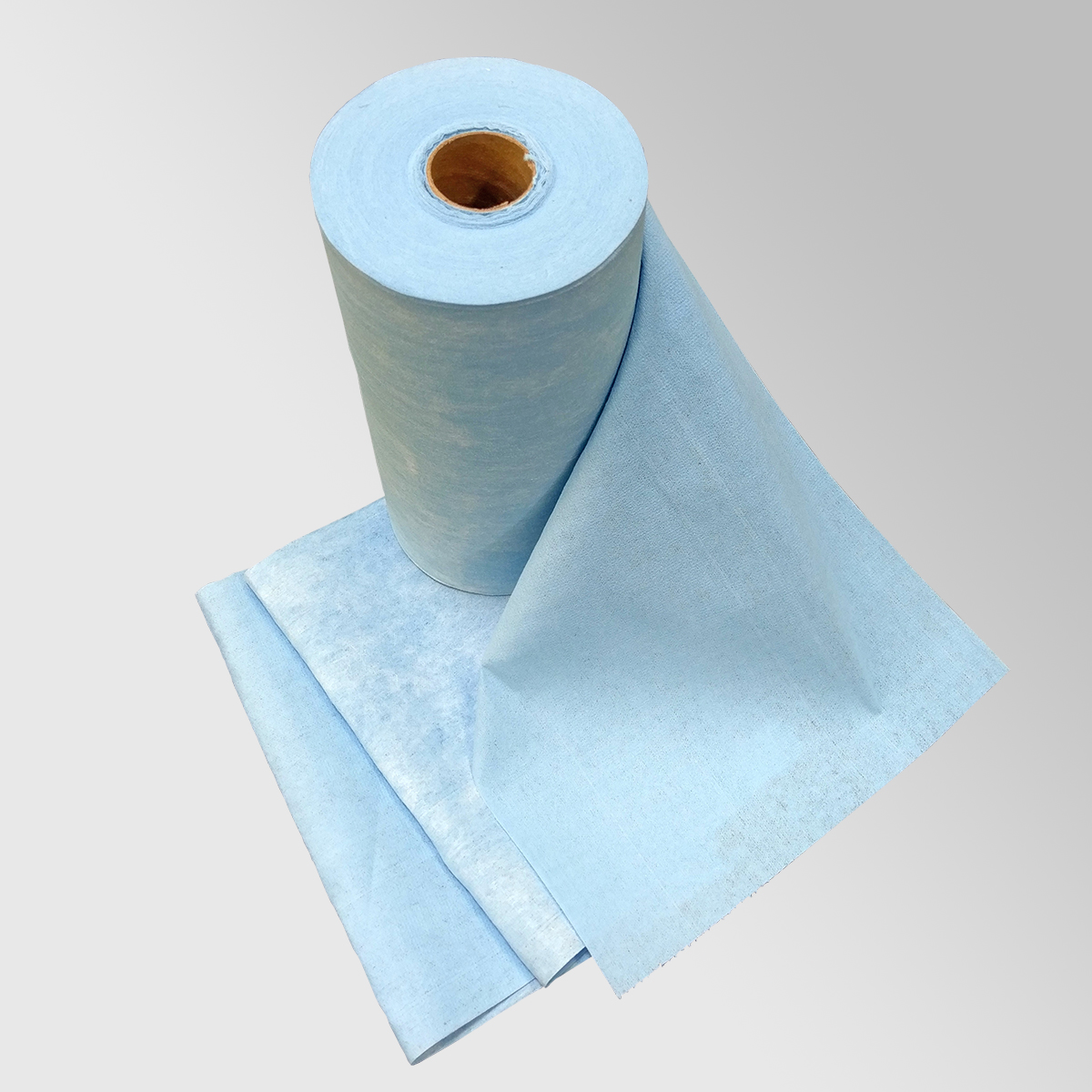

Inkjet primer for plastics primer

Additionally, the inkjet primer for plastics from Boston Industrial solutions works with all LSE plastic substrates. This primer will will 100% work on any plastic substrate.

The Natron PP3 Plastic Primer is used to:

- Reduces product surface tension for better bond

- Guarantee ink adhesion polypropylene & polyethylene

- It is also perfect for screen printing or pad printing applications

The PP3 inkjet Primer for plastics comes in several sizes. We created this knowing that different customers have different needs.

Check out Priming is the solution article here

Using the Natron™ Polypropylene adhesive primer

Lastly, TP Series is an all purpose ink for pad and screen printing on plastics. With the primer, the printed surface is enhanced by this advanced colorless plastic primer. The primer cleans the surface, leaving a shinny film. This prepares the substrate to receive the ink.

Learn more about printing pre-treatment methods and UV ink primers for inkjet printing

Another substrate that is a challenge to print is glass. Learn more about G1 Glass primer.