Pad printing on plastic

Pad printing, also known as tampography, is a printing process that allows for the transfer of complex, detailed graphics onto flat or contoured surfaces, e.g., injection molded plastic parts. It is a popular choice for printing on plastic products due to its versatility, accuracy, and cost-effectiveness.

The process of pad printing on plastic begins with the creation of an image on a printing plate. Pad printing plates typically made of photopolymer or metal. The plate is then coated with a layer of plastic pad printing ink. A cup or a doctor blade removes the excess ink from the plate, leaving a thin film of ink in the image. Then a silicone pad presses onto the plate to pick up the ink. The pad then compes into contact with the plastic product, transferring the ink onto the surface.

Benefits of pad printing

One of the benefits of pad printing is that it can print on irregularly shaped surfaces. It is also perfect for printing products with small, intricate details. To accurately transfer an image, the silicone pad conforms to the shape of the product. In addition, the pad printing process is capable of printing on a variety of plastic materials, including ABS, PVC, and polycarbonate, making it a versatile choice for printing on plastic products.

Additionally, Pad printing is also a cost-effective printing method. It requires minimal setup and cleanup time. Also, printing plates can be used for multiple print runs. The printing process itself is also relatively fast, allowing to produce large quantities of printed products in a short amount of time.

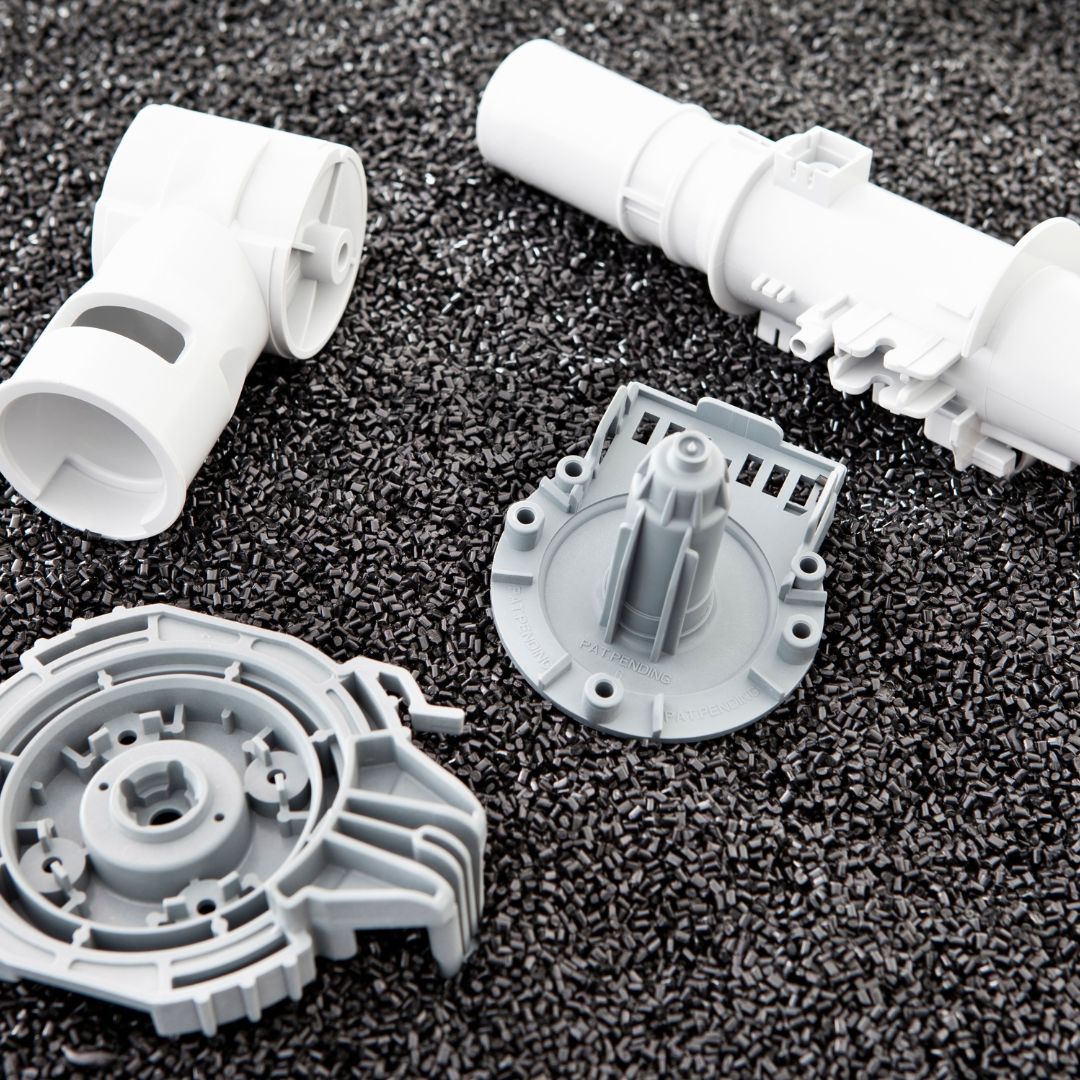

Types of plastics

Plastic materials vary extensively. There are simple plastics which are easy to print and complex plastics which require pre-treatment for the pad printing ink to adhere to. At Boston Industrial Solutions, Inc., we offer the best pad-printing inks for plastic substrates. Common plastics substrates include treated and untreated Polypropylene (PP), acrylics, polystyrene, polycarbonate, ABS, PVC, Terpaulin, Polyester, PET, Nylon, Tritan, and many more. These plastics are in many industries such as packaging, medical-device, marine, cosmetics, fashion, promotional items etc.

Cleaning and pre-treating plastic substrates

There are several factors that to consider prior to printing. The first one is printing preparation. The purpose for this is to combat any impurities that might affect ink adhesion. Examples of impurities include oils, waxes, plasticizers, etc. Before printing, remove impurities by cleaning the substrate with isopropyl, denatured ethyl alcohol, or cleaners designed for specific materials.

Pre-treatment methods include primers, flame, corona, and plasma. We have two types of primers for plastics. Learn more about the Natron PP Primer and Natron PP3 Primer.

Which ink is used for pad printing on plastic?

Natron TP Series ink is the best ink for pad printing on plastic parts. While Boston Industrial Solutions, Inc., has several pad printing plastic inks, TP series is the best in for printing plastic substrates. TP series is a 1- or 2-component printing ink. It is fast drying, high-opacity, high-gloss, very smooth, and has a high abrasion resistance. TP is best used for plastics such as polycarbonate (PC), pre-treated polyethylene (PE), Tritan, Bioplastics, pre-treated polypropylene (PP), polyurethane (PU), ABS, and more.

Check out our Natron SE ink for printing on silicone rubber

Post-treatment of pad-printed parts

Post-treatment of plastic pad printed parts is the drying process that happens after printing. The Natron TP series will dry to touch right after printing and will continue to dry and crosslink with the substrate for a full cure. Note that drying involves removing the solvent from the ink film. Curing on the other hand is achieved only after the ink has completed the chemical reaction required for maximum adhesion, as well as chemical- and mechanical-resistance. All inks continue to cure after drying.

To speed up ink drying and chemical reaction, consider using a heat source such as an oven.

Visit our YouTube channel to learn more about pad printing inks