LOW FRICTION COATING FOR SILICONE – STC 370HP

Natron STC 370HP is a clear-translucent matte coating designed to reduce the coefficient of friction (Low CoF silicone coating) on silicone rubber. This coating reduces the friction force of molded and extruded silicone elastomers. Another term for this coating is silicone soft touch coating for silicone rubber. This coating uses the SC45XHP catalyst to activate the soft touch coating.

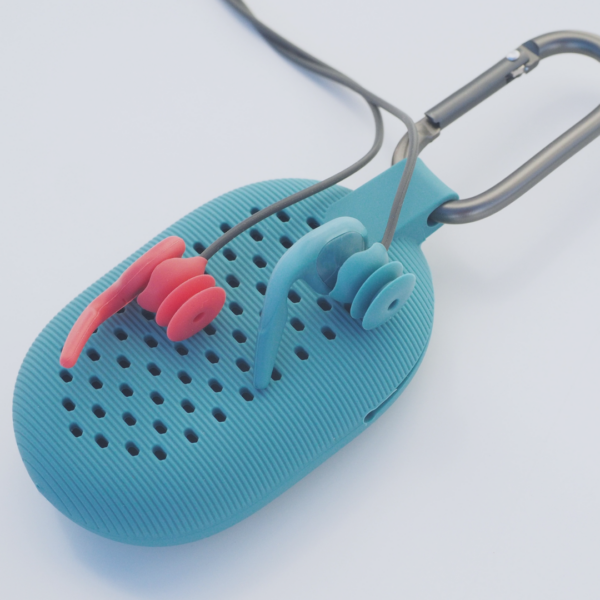

This soft-touch coating is suitable for medical device applications, electronics, and other products designed to contact the human body. The function of this soft touch coating for silicone is to protect underlying prints, markings, rubber products, and for decoration. It can also increase the product’s value.

Additionally, this coating coats faux leather.

What is the coefficient of friction of silicone?

Natural silicone rubber is quite tacky. Generally, the silicone coefficient of friction is approximately 1.0 in most cases. So, use the STC 370HP silicone coating with a low coefficient of friction to reduce silicone rubber friction.

The soft-feel silicone coating Natron STC 370HP low friction coating for silicone rubber is intended for spray coating onto silicone rubber products. The coating needs to be dried and cured at 275°F–400°F, depending on how dense the silicone substrate is.

The SC45XHP catalyst is available in 100g, 200g, and 1 kg size containers.

Boston Industrial Solutions, Inc. designed and formulated STC 370HP for spray coating on silicone rubber products.

The 370HP low friction coating for rubber:

Dry and cured STC 370HP smooth coating for silicone features:

- Clear / Matte finish,

- Soft smooth feel,

- Friction resistant,

- Dust proof,

- Protective cover / improved adhesion on silicone.

Use the Natron STC 370HP to reduce friction in platinum-based silicone products.

You may also be interested in: Solvents and Catalysts for Silicone ink

This medical device coating gives both consumer and industrial silicone decorators an additional option – coating on molded silicone rubber products. With this products, decorators can alter the look of SE silicone ink prints; from gloss finish to matte finish.

Lastly, the STC 370HP low friction coating for rubber adheres very well onto products made of silicone rubber. Silicone and plastics decorators Worldwide can now take advantage of the benefits offered by the STC clear: beauty, function, economic value, durability, and ease of use. Additionally, this flexible low-friction coating is a replacement for parylene.

This coating typical applications include industrial, medical device, and consumer soft touch coating for silicone rubber products is available in 1Kg, 4Kg, and 20Kg containers.

For more information on the Natron STC silicone soft touch coating and our other silicone products, please visit our silicone rubber product page.

Boston Industrial Solutions, Inc. manufactures and provides advanced printing inks, equipment, supplies, and solutions to industrial, medical, toys, and promotional companies worldwide. Boston Industrial Solutions, Inc. is the global leader of silicone inks worldwide. For more company news new products, and instructions videos please visit www.bostonindustrialsolutions.com/news/

Learn more about our high friction silicone for textiles.