PAD PRINTING INK FOR TEXTILES, EPDM, SOFT TOUCH, AND SYNTHETICS

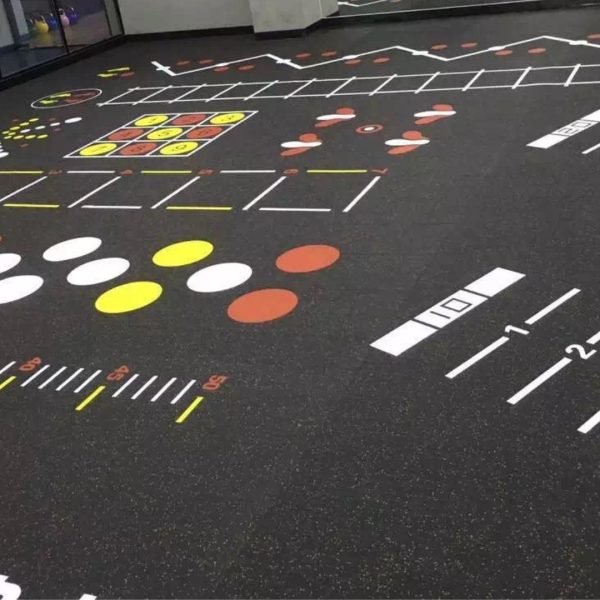

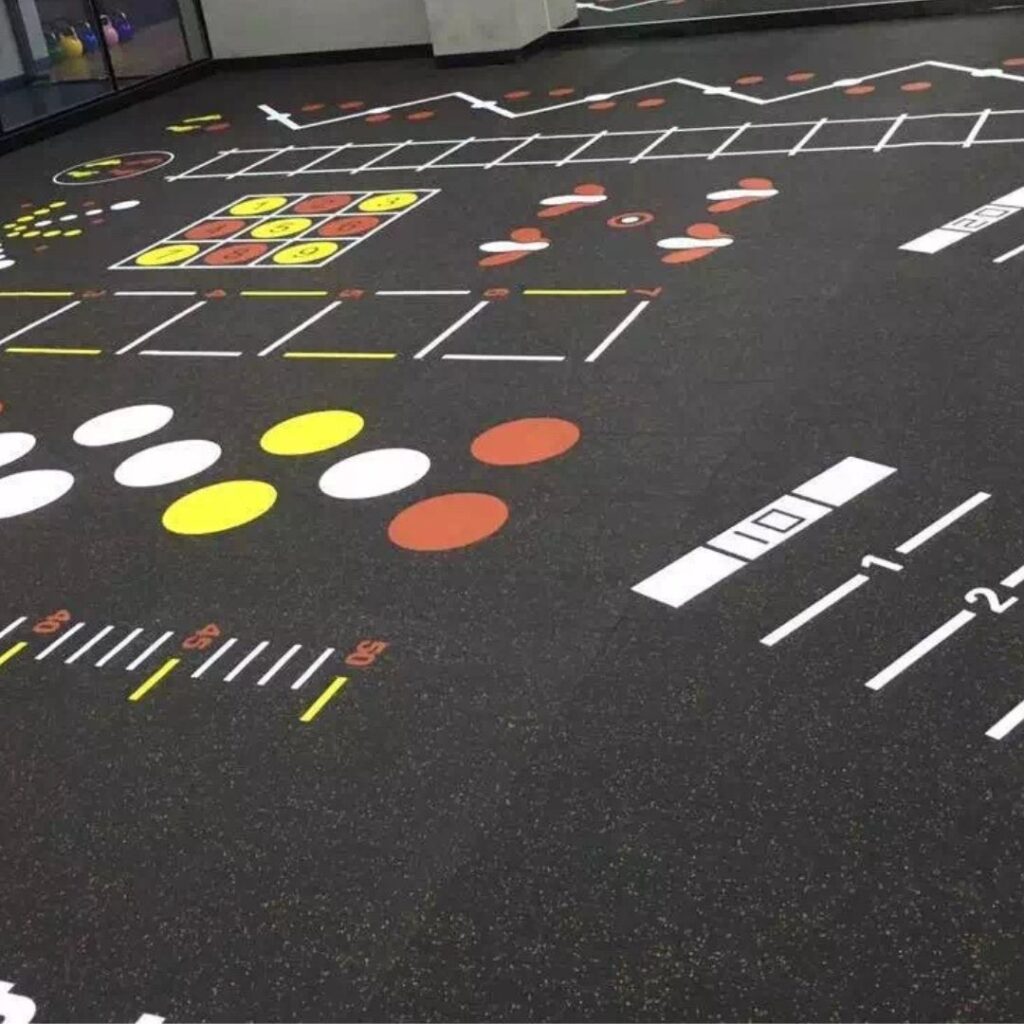

ST pad printing ink is an easy-to-print, ultra-fast-drying, high-opacity, 1- or 2-component pad printing ink for soft touch materials, rubber, apparel, and natural and synthetic fibers. This ink is durable and flexbile. It can also withstand many industrial washing cycles. As a result, it is the best ink for t-shirt care label printing, shoes, industrial rubber marking, and rubberized soft-touch promotional products. Typical applications include Printing on Stress Balls, Sporting Goods, Skateboard Wheels, Soft Touch Surfaces, Soft PVC, ID Cards, Binders/Report Covers, and Textiles.

Also, with the hardener added, the ST Series ink film is much more resistant to mechanical wear. Even after hundreds of washings, this printing ink will not fade because we only use pigments with high fade resistance. The pot life of the ink-hardener-solvent mixture is 6–8 hours at room temperature (70°F and 40–65% RH). After adding the i-300x pad printing hardener, the ink-hardener mixture becomes chemically reactive and must be processed within 6–8 hours. Please see TDS for additional information.

Like all other Natron printing inks, the ST series is classified as non-toxic (NT)—the pigments are free from heavy metals. For more information, please see our safety data sheets, which are available in accordance with EU and US regulations. Additionally, the product label has the primary indications displayed.

The Natron ST pad printing ink is also available in six neon (fluorescent) colors, four metallic colors, and 23 high-opacity standard colors. All colors in this ink series are inter-mixable.

- Highly flexible ink film for maximum wear comfort

- Very good resistance to industrial washing

- High opacity makes it ideal for printing on dark substrates.