Using the right type of ink in the tagless printing process significantly improves the quality and durability of the print. The ink for tagless printing consists of critical components that are essential for delivering a perfect print. Furthermore, ink components are added to enhance its usability. For these reasons, it is important to fully understand the ink to deliver durable, vibrant prints.

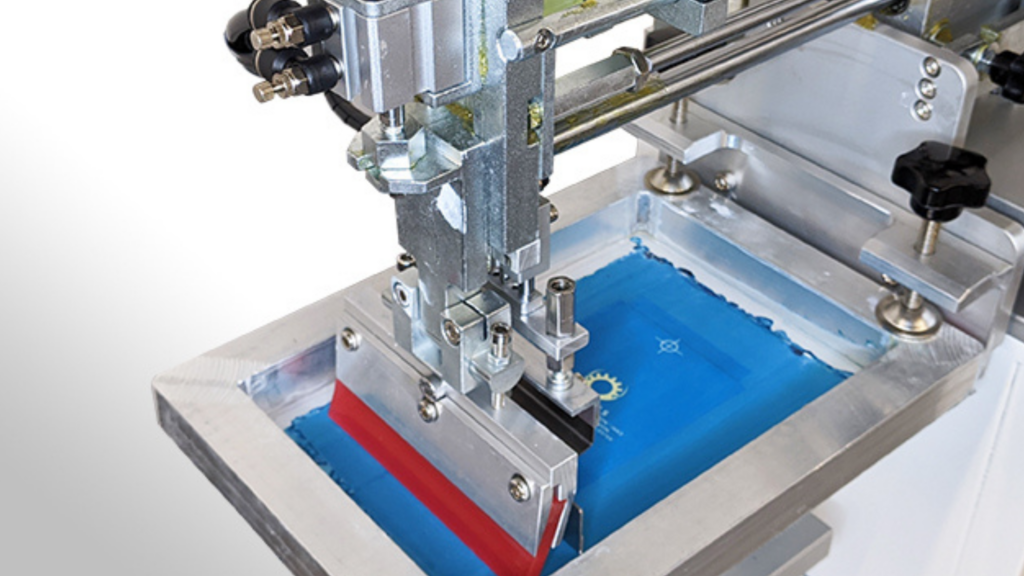

Tagless pad printing works the same way as any other pad printing process. Pad printing is the process of transferring a 2-dimensional image onto a part or a substrate. This printing process works for both two-dimensional and three-dimensional objects. It is important to note that this process utilizes a pad printer machine to label garments.

A pad printer has several critical components that enable it to deliver a print. These components are:

Each new design requires a new plate. It is also important to note that if an artwork has multiple colors, each color requires an additional etched plate.

There are two types of tagless printing processes. These are the tagless screen printing process and the tagless pad printing process. To get an excellent print, it is important to use the right garment printing ink for each type of printing application.

The pad printing process uses a solvent-based pad printing ink—the Natron ST Series. The ST series, which is our standard tagless pad printing ink, is available in a wide range of colors. In cases where you need to print high-opacity prints, we recommend screen printing with the SilTex HD Series and the S150 screen printing machine. This printing process delivers high-opacity colors.

The SilTex silicone screen printing ink uses a different catalyst and solvent than the ST Series ink. Additionally, these inks offer high flexibility, and they never fade or crack. SilTex silicone inks offer maximum durability!

Both silicone-based and solvent-based inks require a solvent to alter the ink’s viscosity during the printing process. There are different solvents that evaporate at different rates, from fast to slow.

During the screen and pad printing process, the solvent evaporates, leaving only the solids (pigments, binders, and resins) on the substrate. Therefore, it is very important to select the right solvent for your specific ink series and the printing environment.

Most people confuse hardener with a catalyst. A hardener hardens the ink, while a catalyst vulcanizes the ink. Hardener is to solvent-based ink what a catalyst is to silicone ink.

Both catalyst and hardener help the ink crosslink with the substrate. Additionally, hardeners and catalysts enhance print durability, which is critical for tagless printing.

Labels printed with SilTex HD and ST Series will last beyond 50 industrial wash cycles.

One of the major advantages of tagless garment printing is that the ink dries to touch instantly. For this reason, it is possible to print a large volume of garment labels without smudging the prints. While the ink dries instantly, the crosslinking takes 24–36 hours—the full cure of the ink. To do adhesion testing, we recommend waiting a full 24 hours before attempting to wash the garments.

For screen printing tagless labels with silicone inks, we recommend using a dryer system. Silicone inks dry for 30 seconds and achieve full cure in 60 seconds.

There are several important safety standards that garments and tagless printing inks should meet. These are CPSIA, Prop 65, NAMSA certification for skin irritation, and Oeko Tex Eco-Passport. Oeko Tex covers the harmful effects on humans and the environment.

Lastly, there is the RSL certification by the large garment manufacturers.

Therefore, it is important to have safe inks when pad printing or screen-printing tags on t-shirts and garments.

Payment Once you submit the order form, we will send you a link to make the payment.

Please accept the terms and conditions by Boston Industrial Solutions.

Your request has been submitted. Someone from the team will contact you shortly.