Are you going with printing to create new products, mark, or decorate the existing ones? Boston Industrial Solutions has been fostering the development of silicone, ink formulation, coating, and printing technology. By bringing together our in-house expertise and global distribution network, we can help achieve excellence in any item printed using the pad, screen, or inkjet method.

Guided by innovative ideas for ink formulations and equipment, we offer comprehensive solutions for printing professionals in Boston, throughout the USA, and worldwide. Discover how our products can cement your production processes while transforming each label and image on your goods into aesthetic perfection.

INDUSTRIAL PRINTING SUPPLIES FOR HIGH-RESOLUTIONS PRINTS

Our inventory includes various high-performance printing necessities for creating one-of-a-kind patterns on a plethora of surfaces. Developed and tested by our in-house team, they can enable you to lock in exceptional quality for all your promotional and end-use items – with no shortcomings in adhesion and color vibrancy.

Inks

Other supplies

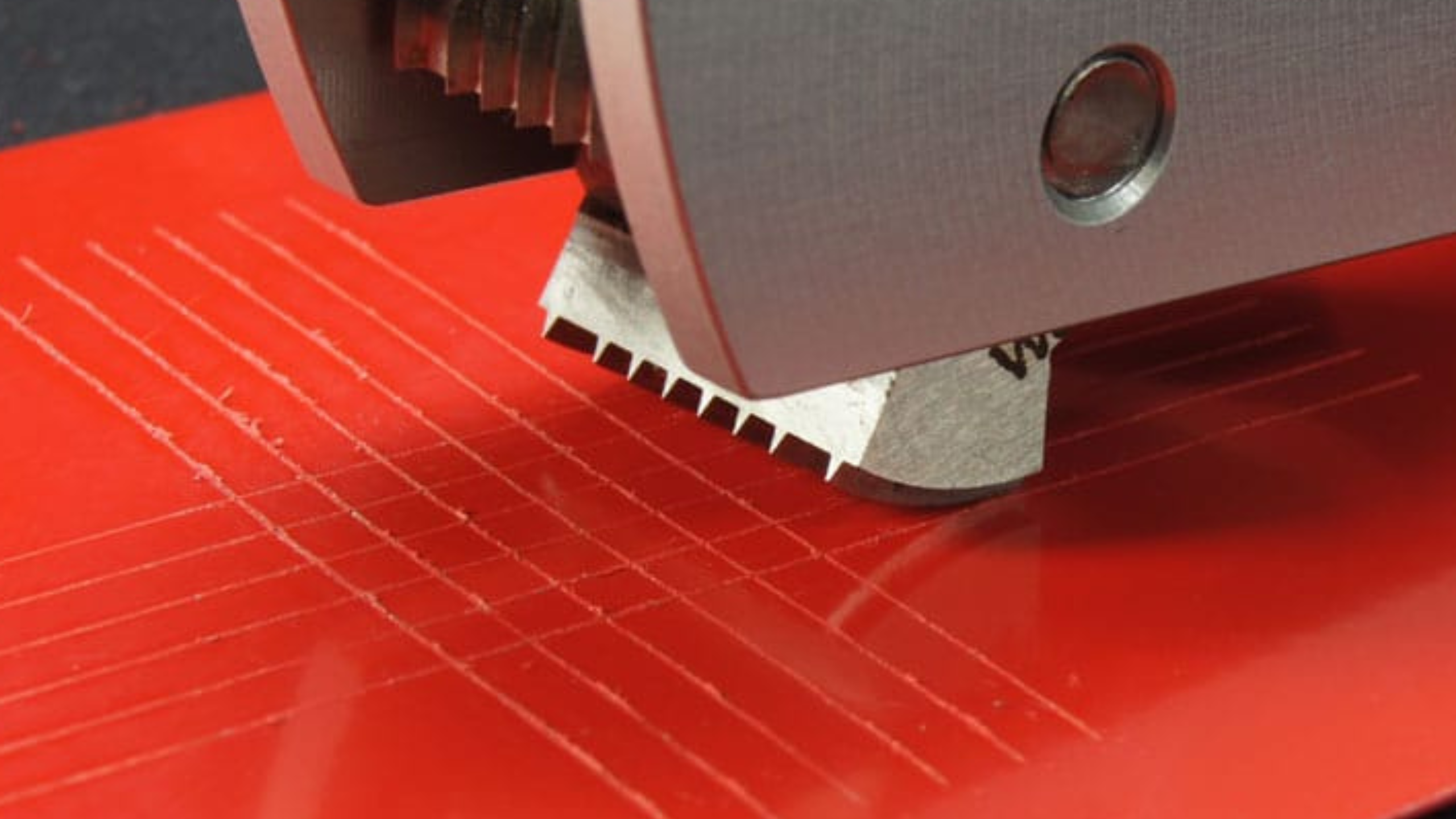

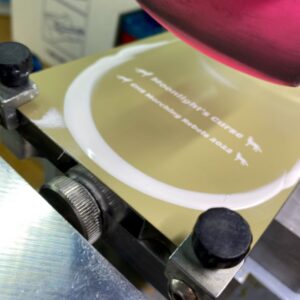

Our pad printing supplies are perfect for adding intricate details to items requiring precision, from miniature promotional products to small parts and components. Designed to fit different pad bases, they contribute to the ink’s adhesion and resistance properties on 3D objects and have you covered throughout multiple print cycles.

With Boston Industrial Solutions, you can also source the required hardeners and bases to enhance seamless ink distribution over the surface. Whether you are looking for a wood or plastic option, our bases are fully adjustable to printing machines and high-performance ink transfer techniques.

Equipment

OUR SERVICES

COLOR MATCHING

We match custom colors and formulate inks

- 24 Hour turn around

- Color Database

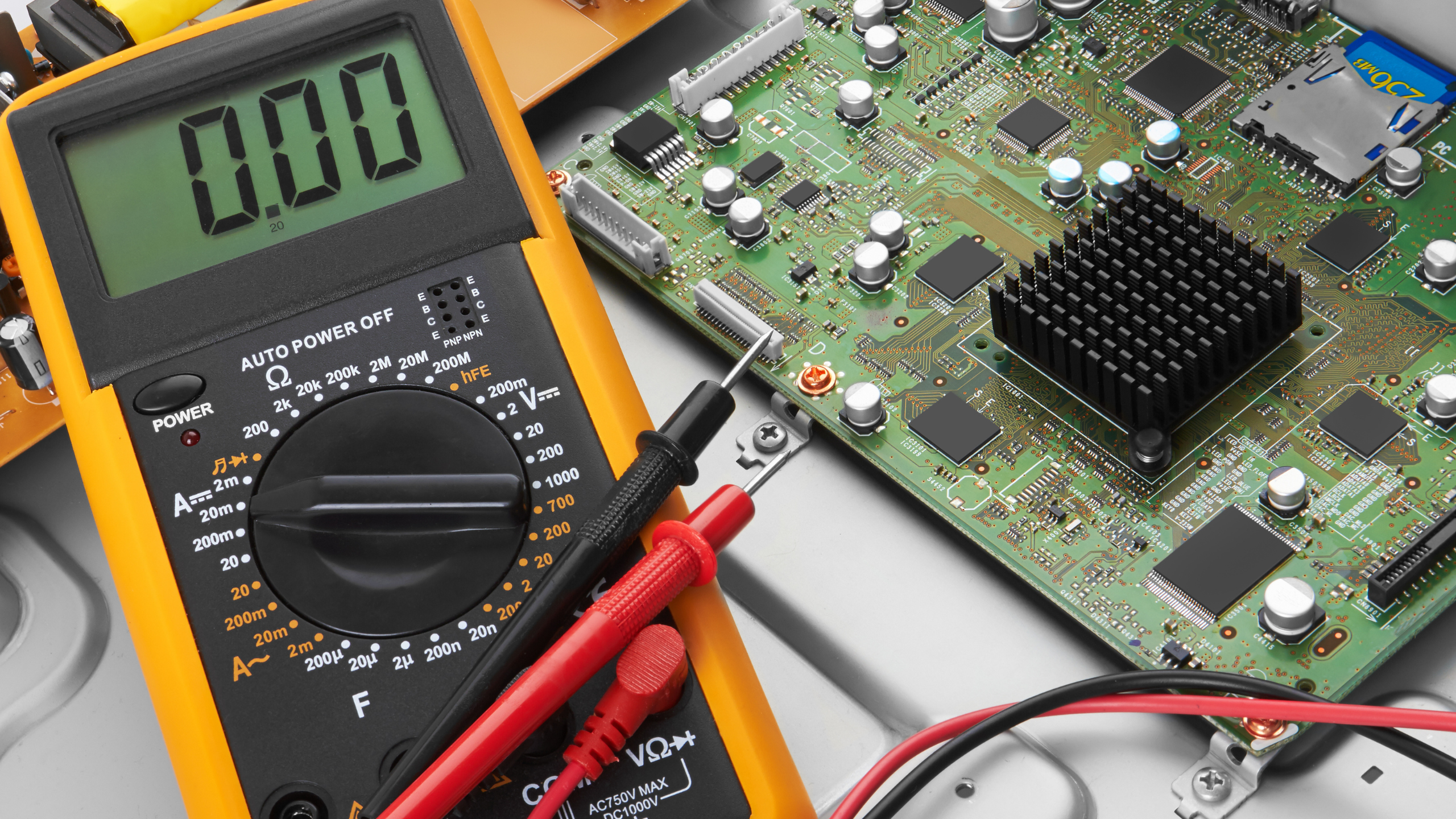

ADHESION TESTING

We match custom colors and formulate inks.

- Detailed report

- Your sample product*

TECHNICAL SUPPORT

What can we help with? To better assist you.

- Over 20 technicians

- Visit the SUPPORT UB

TRUSTED BY THE WORLD'S BEST COMPANIES

APPLICATIONS

From our award-winning cylindrical inkjet printer and flatbeds to our pad printing equipment and lasers, Boston Industrial Solutions is

the top choice for printing experts in all industries. See how some of our customers utilize our equipment!

Sustainable solutions for every business

- Electronics

- Aerospace

- Health care

- Fashion and beauty

- Automotive

We are open to special inquiries

Boston Industrial Solutions welcomes long-term partnerships for streamlined printing processes, technology, and products that set a new standard in the industry. Besides providing printers and supplementary items, we are happy o arrange expert consultations on custom color matching and effective equipment training. Dedicated to optimizing your capabilities and improving end products, our technicians can work out solutions in ink tailored to your applications, industry, and regulatory requirements.

Contact our team to share your special inquiries, get updated on our machines and supplies, or request a sample.

FROM THE BLOG

Pad printing pad problems and solutions

Every manufacturing process, including pad printing, has problems and challenges. While pad printing has been around for a while, both experienced and newcomers encounter printing problems from time to time. It is not uncommon to encounter various pad printing ink-related problems that will affect the quality of the prints. In

The advantages of digital printing

There are various names for digital printing technology, such as direct-to-object printing. In this article, we will review the many advantages of digital printing.

Digital printing on hard goods is not only revolutionary, but it also offers many advantages. This printing technology enables decorators to achieve high-quality graphics on ceramics, glass,

Perfect print on glass

Digital inkjet printing continues to revolutionize printing, and as a result, many signage companies are in search of adhesion promoters to achieve the perfect print on glass. But what is the perfect print on glass? The answer to this question varies depending on the use and personal preferences. However, we