Discover Boston Industrial Solutions’ cutting-edge printing equipment and inks for printing on drinkware. With a commitment to excellence, our inks and state-of-the-art cylindrical inkjet printers redefine the possibilities of customizing drinkware, whether you are printing one or hundreds of drinkware items. Our cylinder printing machines are fast and deliver high-quality prints. This rotary inkjet printing technology makes your product stand out in such a competitive marketplace. Paired with Natron UV printer ink, it is possible to print on any substrate. Additionally, these printing UV LED inks ensure vibrant, durable, and high-resolution prints.

Not only do we offer precision-engineered UV printers, but we also have state-of-the-art pad printing and cylindrical screen-printing machines. Both are excellent technologies to transform ordinary drinkware into personalized, eye-catching masterpieces. Pad printing on drinkware covers 25% of the circumference of the product, making it the ideal solution for printing on mugs and other products that do not require a full wrap. Whether you are printing 360-degree prints or a simple logo, our technology opens creative opportunities for businesses and individuals alike. Let us elevate your printing experience by taking you on a drinkware printing journey. We will show you what is possible when imagination meets precision.

Pad printing and screen printing are the two best printing processes to custom print silicone drinkware, including tumblers, shot cups, and pint cups. For small logos up to 4”, pad printing machines are excellent for the application. However, when printing a full wrap around on silicone tumblers, you need a cylindrical screen-printing machine such as the S300C. These machines, paired with our pad printing supplies and SE Series ink to print on silicone, make it easy to customize your silicone cup.

Digital printing has become a popular method of printing glasses. For example, these digitally printed glasses were printed on the Gyra® cylindrical printer. With this UV printing machine, it is possible to do a full-warp, 360-degree print. Additionally, this machine eliminates any visible seam. You cannot tell where the artwork starts and ends. To digitally print on glass, you need:

Printing technologies for printing disposable cups include pad printing, screen printing, and inkjet printing. Both pad printing and screen printing processes use the MG series ink for glass printing. However, printing on disposable cups with industrial digital printing equipment requires 270 Series UV LED ink. Once printed, it takes seconds to print and stack the cups.

Advances in digital printing have made it possible to easily print on tapered and straight-walled stemless wine glasses. The Gyra® cylindrical printing machine prints a complete 360-degree wrap in full color around these drinkware products. Like mixing glasses, the 314 UV ink for glass is the best ink for drinkware printing applications. Lastly, remember to always use the G1 UV adhesion promoter before digitally printing on glass.

Printing stainless steel tumblers are excellent promotional product giveaway items. Many people use these stainless-steel travel mugs every day, from the gym to the office. As a result, these are perfect for companies to enhance their brands. They are not only visible to everyone, but they are also durable.

Pad printing machines deliver excellent one- or two-color prints. Screen printing machines, on the other hand, deliver excellent results for simple one- or two-color prints. These printing processes deliver high gloss prints when paired with MG Series ink for drinkware printing stainless steel tumblers.

In cases where contract decorators want to print full-wrap, top-to-bottom prints, there is the Gyra cylindrical digital printing machine. Additionally, this printing machine not only prints full wrap on drinkware but is also capable of printing gradients. Additionally, it is also possible to imitate an engraved print. Like glass, stainless steel requires a UV adhesion promoter to pretreat stainless steel. This application uses the M74F UV Adhesion promoter for metals.

Printing on powder-coated metals is not easy because of adhesion challenges. As a result, Boston Industrial Solutions, Inc., has formulated the M87 primer and 314 ink series to enhance UV ink adhesion on coated metals. Prior to printing on powder-coated metals, apply the M87 metal primer, wait for 1 minute, and then print.

Many breweries, bars, and restaurants brand their barware. The MG series inks for screen and pad printing deliver outstanding, durable prints on these products. This ink series is not only excellent on glass and metal, but it is also an excellent ink for ceramic printing. Once fully cured, the MG series has excellent dishwasher resistance. For 2-color custom print barware, use the M2150 2-color pad printer with the MG Series ink. Also consider our pad printing supplies—ink cup rings, inkcups, silicone pad printing pads, electra blue laser plates, and pad printing solvents.

Below, we will review our specialized UV cylindrical printers for drinkware.

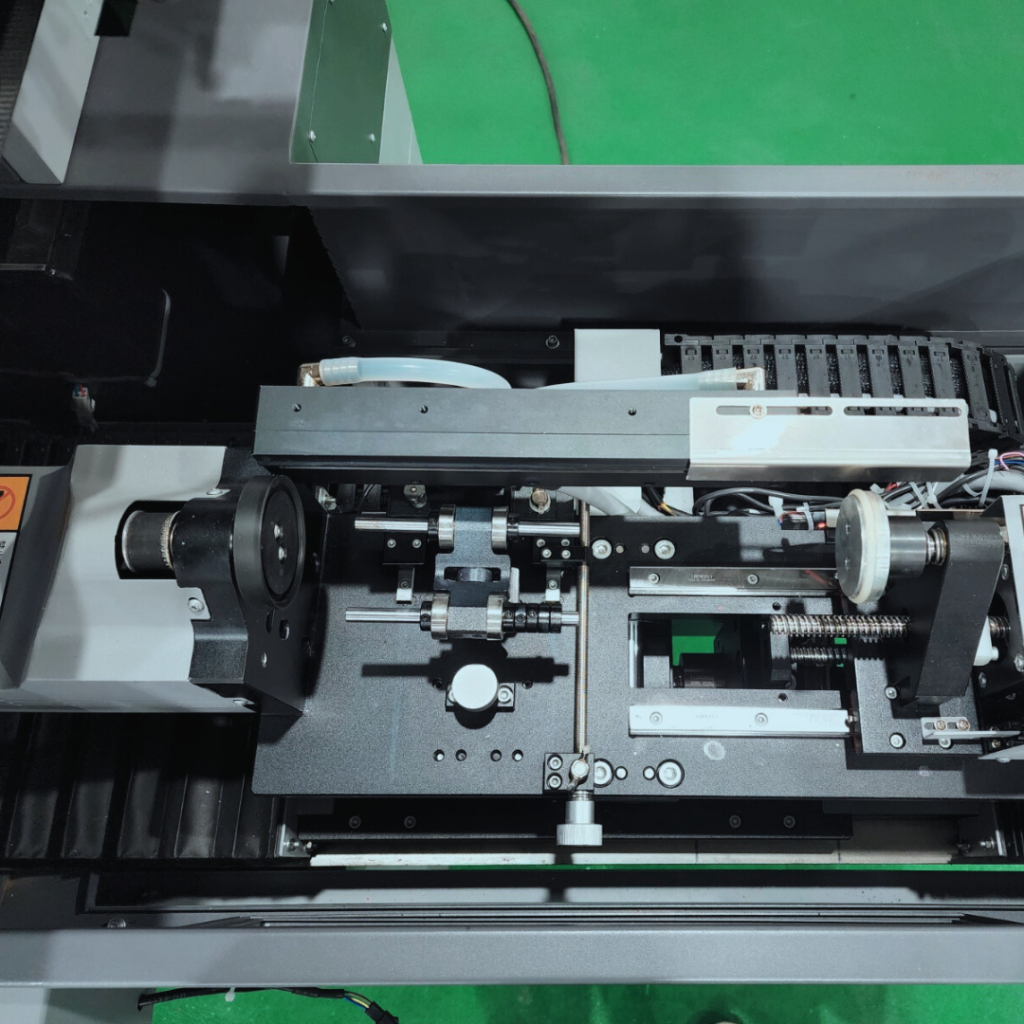

This is an advanced cylindrical inkjet printer capable of printing images up to 215mm in length. Also, with this machine, it is possible to decorate a wide range of products. Examples include acrylic cups, stainless steel vessels, powder-coated drinkware, glass, and more.

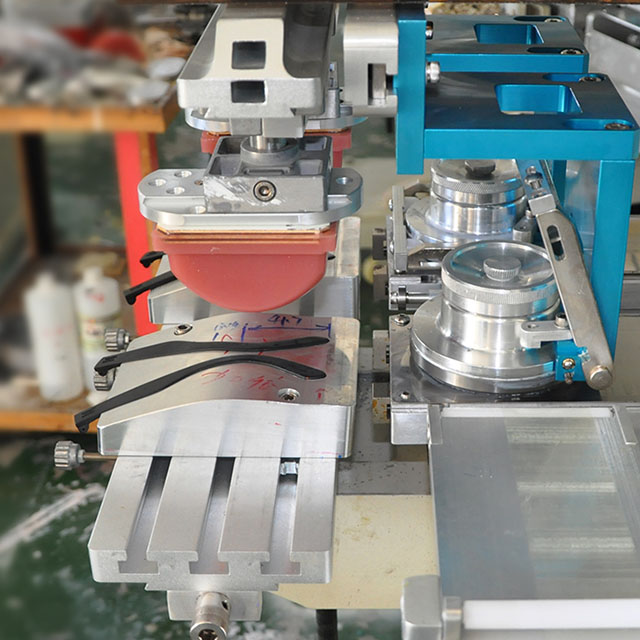

Next, we will discuss the pad printing options for drinkware. Boston Industrial Solutions, Inc., offers 1- to 6-color pad printers to match your intended design outcome.

Boston Industrial Solutions, Inc., offers 1-color pad printers for printing simple graphics. The maximum printing sizes range from 60mm to 150mm.

Whether you are printing 1 color or 2 colors on beer testing glasses or shot glasses, a 2-color pad printing machine is an excellent option. All our pad printing machines can print up to 15” tall objects. Additionally, it is possible to retrofit the machine to accommodate small pad printer ink cups.

Lastly, sometimes you might want to print multiple color drinkware printing. We have 3- to 6-color pad printing machines that allow you to print multiple colors on drinkware. Additionally, these machines have both independent print heads and fully programmable control logic boards.

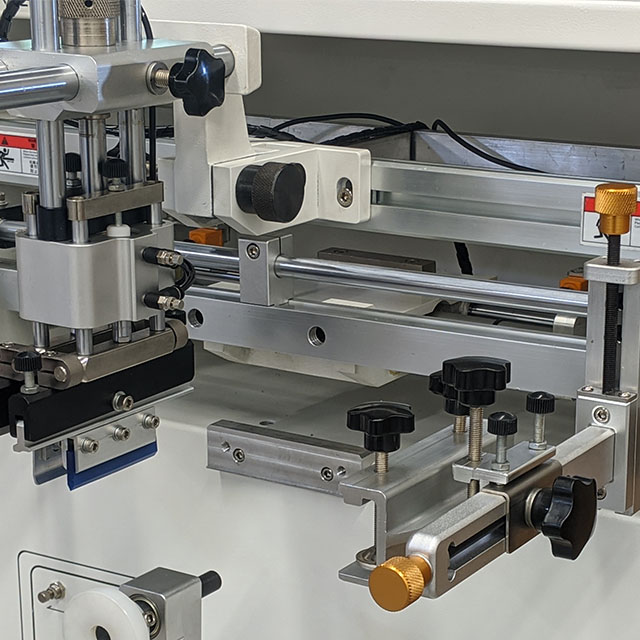

Let’s review screen printing solutions for quality prints on drinkware.

The S300C is an excellent screen-printing machine to handle your one-color drinkware printing applications. Built with industrial-grade materials, the S300C is very durable. This machine features fast and accurate printing. Additionally, it has quick product changeover—less than a second. This makes this machine perfect for new and experienced printers alike. Couple this machine our screen printing inks.

Payment Once you submit the order form, we will send you a link to make the payment.

Please accept the terms and conditions by Boston Industrial Solutions.

Your request has been submitted. Someone from the team will contact you shortly.