How to print pens

Boston Industrial Solutions, Inc. manufactures and supplies printing inks and equipment to the pen printing market. Each month, we deliver thousands of kilograms of ink and supplies to pen printing facilities.

Our printing portfolio consists of machinery specially adapted for printing pens. These include pad printing machines, screen printing machines, laser engravers, and UV inkjet printers. Additionally, we offer inkjet, screen, and pad printing inks and training to support your printing operation. In this article, we will review different methods for printing or marking on pens.

Check out our pad printing supplies and inkjet printing supplies for more information.

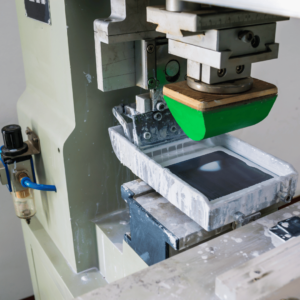

Pad Printing

When printing on narrow, curved, or clipped pens, consider pad printing. Pad printing delivers detailed logos with small text with no loss of image quality. Other advantages of this pen printing method include speed and cost per print.

Screen printing

Most people know screen printing as a method for t-shirt printing. While this is the case, screen printing is a very common printing method for pens as well. It is a process that involves forcing ink through a mesh screen onto a surface. The image is “burned” onto the screen. Only the imaged area allows the ink to pass through. Just like pad printing, it is possible to produce a full-color image with CYMK process colors. Screen printing has several advantages. These include large image printing areas, excellent for large-volume printing, and high opacity on dark substrates. Lastly, this printing method is not suitable for low-volume and irregularly shaped pens.

Digital printing

Digital printing requires a digital flatbed inkjet printer. As many companies transition from solvent printing inks due to climate change, digital printing is an excellent alternative to both pad and screen printing methods. While there are several types of commercial inkjet printers available, a UV inkjet printer is excellent for transfering a 2D image onto a 3D object, such as pens.

A UV inkjet printer uses print heads to place microscopic droplets of ink (CMYKW+VV) onto the surface of an object in order to form an image. To print pens, you need a pen fixture to hold the pens.

With inkjet printing, it is possible to print full-color (photo-quality) images. Use the digital printing method for thicker pens and pens with broader clips. Additional advantages of this printing method include quick job set-up and a low start-up cost compared to four color process screen or pad printing. UV inkjet printers are not suitable for wide-angled prints or pens with large protruding clips.

Other methods for printing on pens

Foil printing uses a heat cylinder to apply film to the intended surface. This is the technology to use for silver and gold prints on pens. As a result, foil printing is not suitable for printing multiple colors because it does not use ink.

Because this method uses a cylinder to apply the image, it is important to make sure that the body of the pen is completely even. Additionally, avoid using this printing method with frosted pens. Major advantages of foil printing include high opaque coverage, an eye-catching, luxurious look, and cost effectiveness.

Laser engraving uses focused light (laser) to etch or mark a design on the product’s surface. Available laser technologies include YAG lasers, CO2 lasers, and UV lasers. The choice of laser depends on the pen material for engraving. A YAG laser is excellent for metal surfaces, while a CO2 laser is excellent for painted surfaces. Engraving is permanent. Therefore, for pens exposed to continuous use or harsh environments, use laser engraving. Additionally, laser engraving offers quick, precise production and is eco-friendly. Use this method for the most elegant finish and exclusive metal pens.

Printer for pens

In addition to pad printing machines, we offer flatbed UV printers for printing on a wide range of products, including pens. Visit our UV printer sections to learn more about our product offering.

Ink for pen printing

At Boston Industrial Solutions, Inc., we pride ourselves on manufacturing some of the most advanced inks available on the market today. Printers around the world use these inks to print on a wide range of substrates. There are many types of materials used to make pens around the world. To mark and print on these different materials, we need high-quality inks.

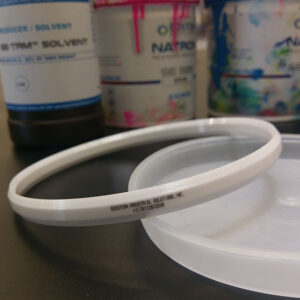

Screen and pad printing inks for pens:

For metal and hard plastic pens, the Natron MG series is an excellent ink to use. This ink features high gloss, opacity, and excellent print-ability. Learn more about glass printing methods.

Most plastic pens, including recycled PETE (rPETE), should use the TP Series ink line. For all other plastics, the EK series, a one-component pad printing ink, is an excellent choice.

Soft-touch coated pens have become very popular due to their velvety feel and luxurious look. For this type of material, use the Natron ST Series soft touch inks, which has a very high opacity and matte finish to match the soft-touch look.

Inkjet printing inks and other supplies.

For hard-to-print pen materials, especially with UV inkjet printers, we offer adhesion promoters. Click here to learn more. Lastly, we not only offer great inks for printing on many materials, but we also offer inkjet supplies, pad printing supplies, and screen printing consumables to keep your printing operation running smoothly.

For any additional questions on printing, please feel free to contact us or visit our YouTube channel to learn more about silicone and printing technologies.