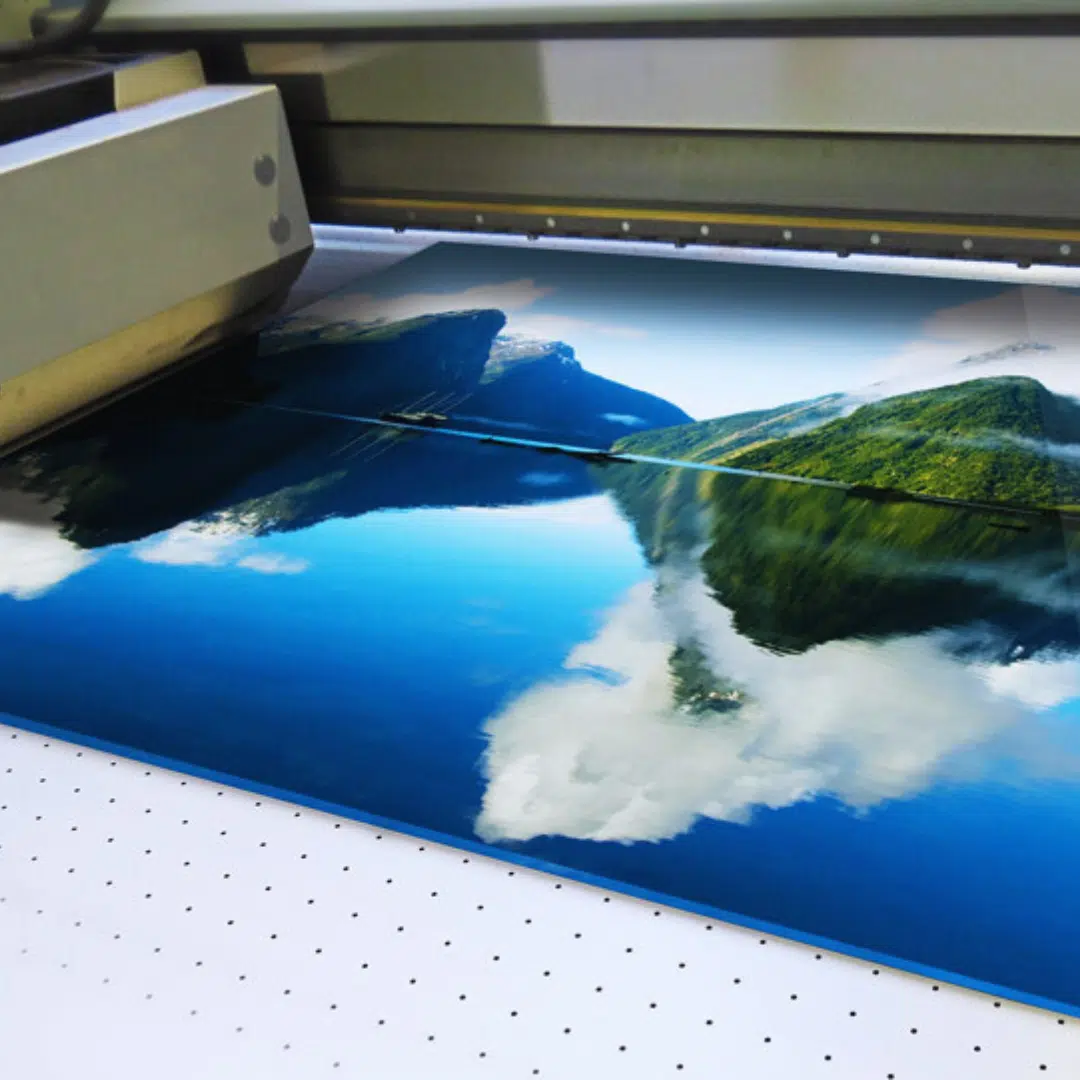

In this blog article, we will review UV printing on acrylic materials. UV printing utilizes ink that dries instantly on exposure to ultraviolet (UV) light. There are two types of UV printing. These are:

- UV/UV LED screen printing transfers ink through the screen onto the part using a squeegee. The ink passes through the screen and onto the object. The ink dries instantly when exposed to UV light in a UV drying tunnel. The ink, which has photo initiators, enables it to instantly dry onto surfaces, specifically acrylic in this case.

- UV/UV LED Digital printing, on the other hand, uses UV inkjet inks to print a digital image directly onto an object.

Both printing processes are sustainable—UV inks are VOC-free. The latter method utilizes digital printing equipment, either a flatbed UV printer or a cylindrical digital printer.

There are several advantages to UV printing on acrylic. These include the ability to print textured special effects and to combine the available colors to produce vibrant prints.

What is UV printing on acrylic materials?

Acrylic, also known as plexiglass, is a transparent plastic material with outstanding strength, stiffness, and optical clarity. There are many applications that use acrylic material. These applications include awards, picture frames, furniture, glass substitutes, signage, displays, packaging, retail displays, promotional products, etc.

What Are the Benefits of Using UV Printing on Acrylic?

There are many benefits to using acrylic fiber for UV printing.

- Visual Appeal:Acrylic fiber has a glossy appearance like glass, lending a visually appealing look to printed products such as signage and branding logos.

- Customization: You can easily customize acrylic fiber into desired sizes and shapes, which allows for flexibility in design. They help enhance the overall appearance of printed materials.

- Weather Resistance: Acrylic fiber is resistant to weather conditions, making it suitable for outdoor applications where exposure to sunlight and other elements may occur. UV prints on acrylic fiber are known to maintain their quality and colors over time.

- Durability: The inherent strength of acrylic fiber ensures the longevity of UV prints, even with prolonged exposure to UV light. This ensures that the printed materials remain vibrant and intact.

- High-Resolution Printing: Acrylic fiber assures high-resolution printing with vibrant colors and textured effects, resulting in visually striking and professional-looking printed acrylic materials.

- Versatility: Signs, posters, packaging prototypes, and specialty industrial applications can all benefit from UV printing on acrylic fiber.

UV Inks Used for Printing on Acrylic

The common types of UV inks used for printing on acrylic materials are LED curable ink and UV screen printing inks.

UV digital printing uses UV LED inks. Many contract printers use this type of ink to print on acrylic boards, PVC, metals, glass, etc. Boston Industrial Solutions, Inc. has several UV inks for digital printing, e.g., the 314 UV inkjet series and the 270 UV inks. These inks are vibrant, durable, and resistant to the elements.

On the other hand, UV screen-printing inks function similarly to standard solvent screen-printing inks. Learn more about our UV screen printing inks.

While both UV inkjet inks and UV screen printing inks are excellent for printing on acrylic, the material requires pre-treatment for the UV inks to permanently bond to it.

UV Adhesion Promoters for Acrylic

UV adhesion promoters enhance UV ink adhesion on acrylic and other materials. These digital promoters ensure the ink is strong on acrylic surfaces. The Natron® M74F primer is the best UV adhesion promoter for acrylic materials. The other excellent promoters for acrylics are the M87 and MD3 adhesion promoters. These adhesion promoters are also excellent for metals. MD3 is excellent for phenolic PCB boards. Plastic primers such as the PP Primer have negative effect on acrylic.

These UV adhesion promoters provide a reliable solution for achieving vibrant and long-lasting prints on acrylic materials.

How to Choose the Right UV Adhesion Promoters for Inkjet Printing

These factors include:

Material compatibility: The adhesion promoter must be compatible with the substrate. Choosing the wrong primer will negatively affect the surface of the acrylic.

Application Method: The application method is another important factor to consider when choosing a UV digital primer. Spray guns, wiping, or UV jettable adhesion promoters are the methods available for applying primers. It is important to choose a primer that is cost-effective to apply to the acrylic surface.

Durability: Choose UV adhesion promoters that offer durability against scratching, weathering, and UV exposure. They must maintain print quality over time.

Safety: Run tests to ensure that the chosen adhesion promoter is safe to use. It must comply with relevant safety regulations and environmental safety standards.

Conclusion

Acrylic is a very important material in the signage and award industries. These industries use UV inkjet printing to create vibrant prints. To make the images bond and last on acrylic, it is important to use adhesion promoters. Boston Industrial Solutions, Inc. has formulated excellent UV inks and UV ink primers for printing acrylic materials. Visit our products page to learn more about our inks and primers.

If you have any questions, visit our YouTube channel, or visit our support hub to learn more about it.