Boston Industrial Solutions, Inc.’s goal is to offer industry-standard, sustainable printing products. We continuously innovate to provide tangible products that eliminate waste. Additionally, we work very hard to offer safe products to our customers and the environment. Every product undergoes rigorous testing to make sure that it meets these goals. Our in-house compliance team not only oversees changes to environmental regulations but is also proactive in pointing out areas for improvement.

Our Natron® ink series products meet very strict US regulations, European toy safety standards (EN-71), RoHS, and many other regulations.

Independent labs like Toxicon and QIMA have certified each of the Natron inks to be free of lead, phthalates, carcinogens, and other harmful substances, as required by the Consumer Product Safety Improvement Act of 2008 (CPSIA). Additionally, these sustainable printing supplies comply with the Safe Drinking Water and Toxic Enforcement Act of 1986 (California Prop. 65).

Our MG, BX, and SE-F Series are class VI certified—this makes these products safe to print on products that come into contact with the human body.

The Natron® ST Series pad printing ink, silicone screen printing inks, and the STC370HP do not contain Azo dyes, restricted heavy metals, or PVC, as certified. Additionally, all these products do not cause skin irritation.

The health of our customers, the customers of our customers, and the environment are important to us. At Boston Industrial Solutions, Inc., we are always looking for better ways to improve our products to meet strict environmental standards. We not only test our products internationally, but we also use independent labs to test them. This feedback is critical and helps us to continuously improve and make our products, services, and practices sustainable.

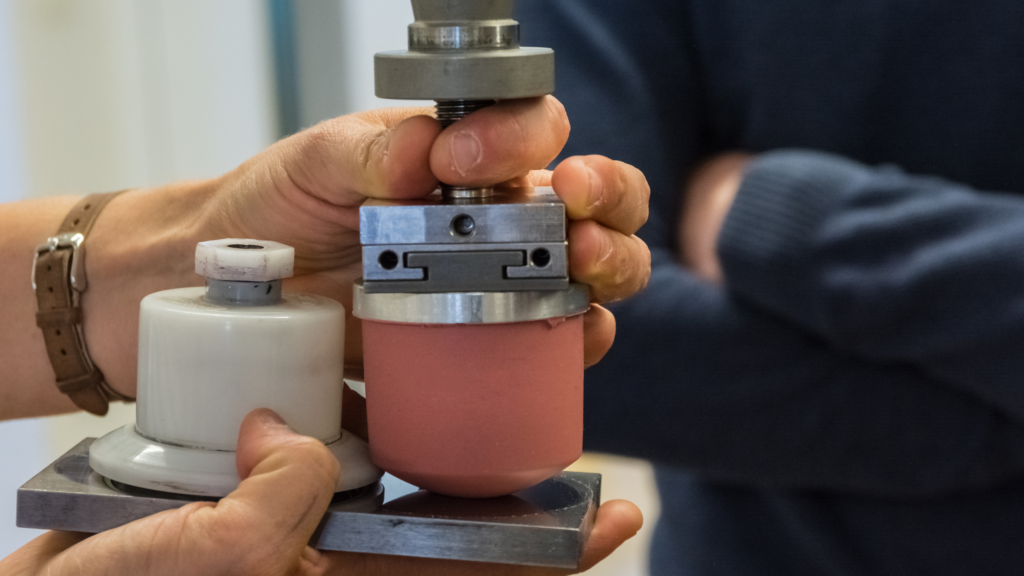

An ink cup is one of the most important components of a pad printing machine. We have created sustainable cups that do not use wasteful plastic inserts or harmful coatings. Our cups last twice as long as any other cups on the market today. Additionally, we use safe zirconia material for the replacement ink cup ceramic rings. This material is not only inert but also lasts a long time.

All our ink cups are resistant to solvents and require less solvent for cleaning. Additionally, we offer VOC-free cleaning solvents to help you keep your rings clean and durable.

Both the SilTex silicone inks for textile screen printing and the ST Series pad printing inks do not contain harmful chemicals such as naphtha, PAH, BPA, and cyclohexanone. These are the safest inks for printing on apparel on the market today.

These ink series comply with Eco-Passport, CLP/GHS (EC 1272/2008), EN 71-3, Reach (EC 1907/2006), RoHS, and ISO DIS 6330.

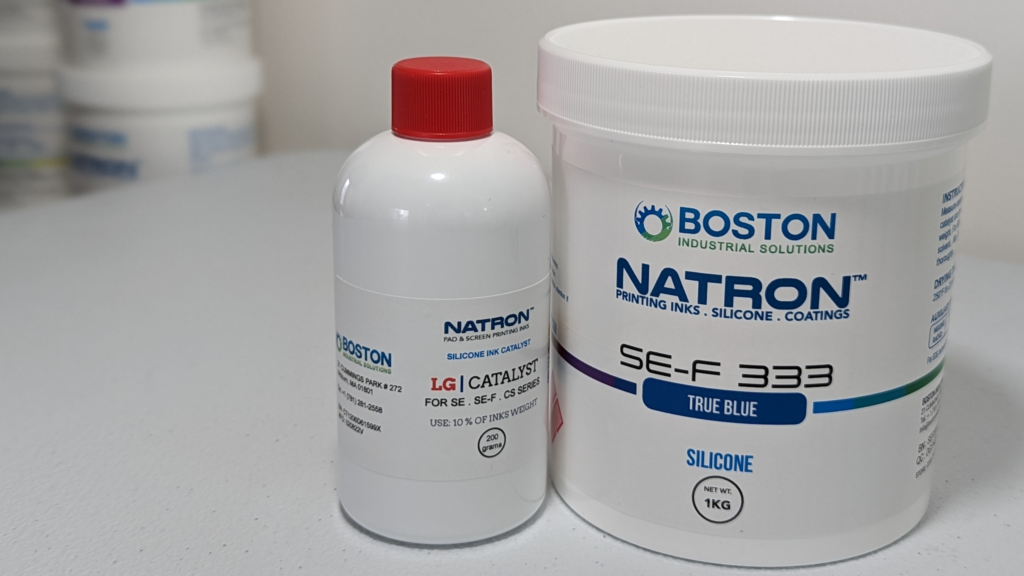

Many of our products do not contain harsh chemicals—they are eco-friendly and easy to use. All our silicone printing products are not only safe to work with, but they are also eco-friendly. Each of the inks does not contain heavy metals. Additionally, they are excellent for printing on non-single-use silicone products, which are safe for the environment.

Our textile screen-printing silicone inks use less energy compared to plastisol to dry and cure. Additionally, these inks are not only BPA-free, but they last forever. They are non-irritant, lighter, and safe to screen print on many clothing applications.

As companies migrate to UV ink and digital printing, at Boston Industrial Solutions, Inc., we continue to innovate and provide sustainable inkjet printing supplies and solutions. Our UV screen printing inks and inks for inkjet printing do not contain NVP (N-vinyl-2-pyrrolidone) or other harmful chemicals.

Additionally, we not only provide eco-friendly UV adhesion promoters, but we also provide reactive UV/UV LED inkjet inks that work effectively with the most popular print heads. Our UV inks use less energy compared to any other inks on the market today.

The traditional plate-making process not only consumes a lot of time and energy, but in certain cases, it also uses chemicals that have high VOCs. Compared to the traditional plate-making process, laser etching eliminates waste while still offering high-quality prints. Photopolymer plate making uses several steps that require the use of film, screen, and plate developer. Each plate made in the photopolymer process generates waste. Additionally, the film and plate are made from environmentally unsustainable materials.

Electra® laser plates consist of 100% recycled aluminum and steel.

All our solvents, hardeners, and printing catalysts do not contain xylene. Additionally, the catalysts for silicone, 300X, and all hardeners (267X, 260X, and 247X) for the MG series are VOC-free.

Ink hardeners are an important component for all 2-component screen and pad printing inks. The hardeners promote ink abrasion resistance. Having safe sustainable hardeners makes them safe to work with.

There are very many consumables used in the printing process. We invest in R&D to develop printing consumables that last longer, reducing waste.

We use a proprietary silicone material to make all our pad printing pads. This material not only has a stronger tensile strength compared to any other silicone on the market today, but it also lasts twice as long as any other pad material.

Lastly, our thick steel plates can withstand over 1 million impressions.

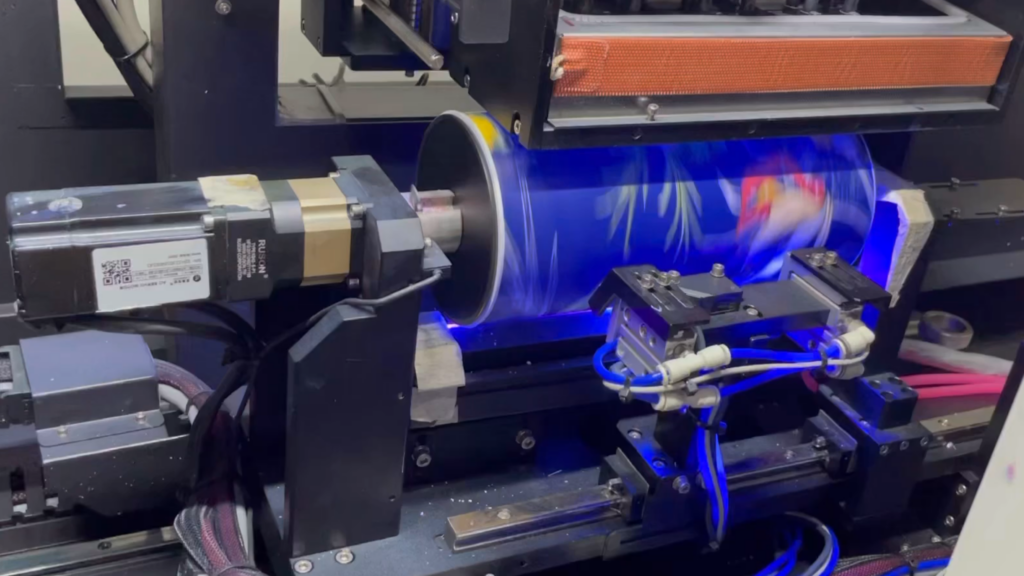

Direct-to-object printing eliminates wasteful paper plastics, shrink labels, and paper from sublimation. Screen printing, tagless printing labels on garments, and digital printing directly onto an object save consumables and waste.