What is a printing pad?

During pad printing, it is important to clean ink from printing pad. This reduces ghosting and improves the sharpness of the print.

Pad printing is also known as tampography or tampo printing. Pad printing is a printing process used to transfer a 2-Dimension image onto a 3-Dimension object. To print a 3-D object use a silicone pad to transfer the image from a cliché (plate) using a silicone pad onto the object. Pad print applications include medical, automotive, promotional, apparel, apparel, toys, etc. some made from silicone.

To print onto silicone rubber products, printers use silicone inks.

Tampo printing with silicone inks can be challenging. This is because silicone ink will stick to silicone substrate (silicone pad). We discussed this in our previous article (Silicone printing problems and solutions).

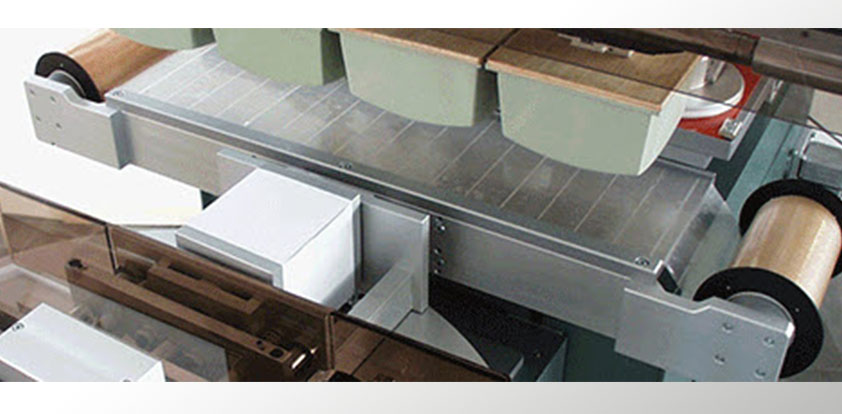

As a result, of silicone ink adhering to the silicone pad this will prevent a clean print. To prevent this we recommend tampo printer machines with a cleaning mechanism. The cleaning mechanism removes silicone ink from the printing pad.

Learn more about our UV adhesion promoters.

How to clean silicone ink from the silicone printing pad

The tampon cleaning mechanism will clean the pad after a few cycles. Pad cleaning pad printer is ideal because it will automate the cleaning process.

Depending on the pad printer that you have, you can program the machine clean the pad after prints.

Boston Industrial Solutions, Inc. can help you get a pad printing machine with auto cleaning mechanism. Automating the cleaning cycles will increase productivity.

Boston Industrial Solutions, Inc. provides other printing supplies to help you with your silicone printing. Contact us for more details.

For the latest news and to learn more about printing technology, please visit out YouTube channel. For any questions, contact us or visit our support hub page.