UV printing has revolutionized the world of printing and decorating. This printing technology offers many advantages that extend beyond vibrant and high-quality prints. In the search for a sustainable printing process, we investigate the environmental benefits of UV printing. Additionally, we will look at how UV inkjet ink and jettable adhesion promoters contribute to a greener and more eco-friendly printing landscape.

We will review in depth how digital printing not only enhances print quality but also minimizes VOCs, energy consumption, and waste. As a result, this will provide reasons why UV printing is an excellent decorating process for businesses that need efficiency and sustainability.

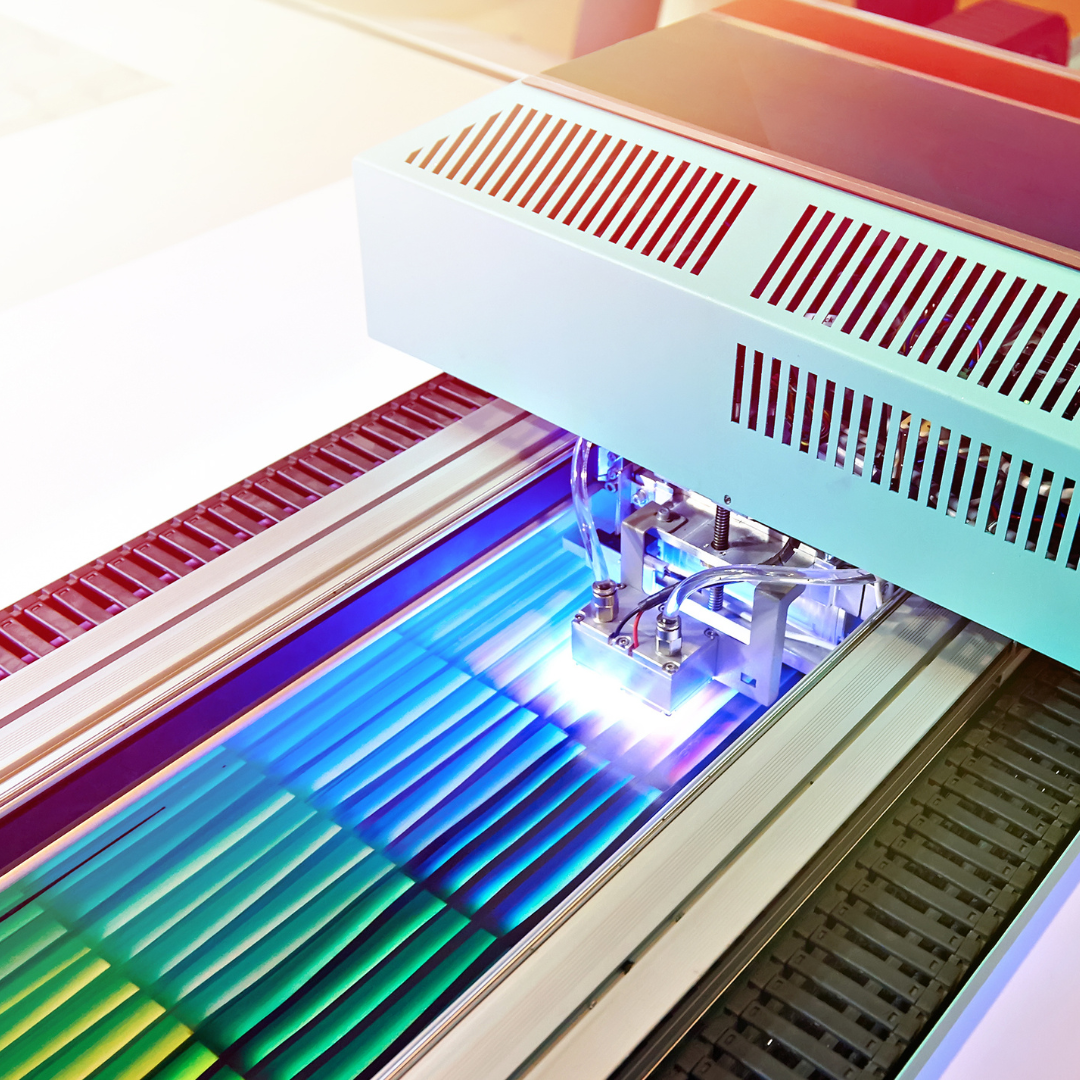

UV Printing Technology Explained

UV printing utilizes ultraviolet light to instantly dry UV inks through a process known as photopolymerization. The UV inks dry instantly on exposure to UV light because of special chemicals called photoinitiators. Unlike solvent inks, UV ink dries instantly. Not only do these inks dry instantly, but they do not emit VOCs and use less energy. As a result, printing and packaging are quick. These printing processes and inks are also environmentally friendly, making them great for the planet.

There are several types of UV inks. These are screen printing inks, pad printing inks, and UV inkjet inks. The former uses the traditional analog printing process, while the latter uses inkjet printers equipped with print heads to jet ink onto a substrate.

Formulators create UV inkjet inks with photopolymerizable compounds, which make them dry instantly when exposed to ultraviolet light. This enables high-speed, high-quality printing on various surfaces. Additionally, with the aid of UV adhesion promoters, these inks stick to many types of materials. Various industries use UV inks to print on a variety of substrates, including paper, plastic, glass, metal, and more, due to their ability to stick to many types of materials with the aid of UV adhesion promoters.

Environmental benefits of UV Printing

UV printing is environmentally friendly compared to traditional printing methods because it typically produces less volatile organic compounds (VOCs). Additionally, the instant drying of the ink uses less energy compared to thermal-cured inks. This reduces energy consumption.

UV printing, especially with UV printers, uses less ink. These printing machines (digital cylindrical printers or UV flatbed printers) use the right amount of ink without waste. These machines mix and print colors on demand, unlike the pad printing process. In pad printing, there is a minimum amount of pad printing ink required to print a substrate. If you fail to fill an ink cup with the right amount of ink, it might not be possible to print or mark your product.

Lastly, the ability to use a few colors to achieve a wide range of color shades also reduces waste. Learn more about the BX Series Pad printing ink.

Comparison of UV inkjet ink with solvent inks

| Aspect | UV Ink | Traditional Ink |

| Drying Process | Instantly dries on exposure to UV light | Air drying or thermal (heat) drying. Additionally, it takes time to cure 36 – 72 hours. |

| Drying and cure Time | Instant drying. 24hr cure.

Perform adhesion testing after 24hrs. |

Thermal cure inks dry in minutes to hours. Air dry and cure requires time. Perform adhesion testing after 36hours. |

| Substrate Compatibility | Compatible with a wide variety of substrates. | Most solvent inks are substrate specific. |

| Adhesion | Poor adhesion on many substrates. As a result, UV adhesion promoters is required to help the ink to stick well to the materials. E.g. M87 UV adhesion promoter for aluminon and coated metals.

|

Adhesion is very good on many substrates except for low surface energy materials. The low surface energy materials require pre-treatment to stick well to these materials. E.g. PP Primer for polypropylene plastics. |

| Durability | Offers good durability especially when the print is coated with a varnish. | Has excellent durability. Some inks are chemical and weather resistant. E.g. MG Series screen printing ink for glass and metals. |

| Color Options | Uses few colors to achieve a wide range of shades. The colors are instantly mixed by the machine to deliver full color prints. | There are many standalone colors. However, printing full color is challenging and time consuming. |

| Environmental Impact | Has very little VOCs. No waste during printing. Uses less energy compared to thermal cured solvent and silicone inks. | Traditional inks contain VOCs. Additionally, some thermal cure inks such as silicone inks for textiles require a tremendous amount of heat to dry and cure. |

| Shelf life | The UV inks have a limited life usually 1 year from date of manufacture. | Has long life, typically grater than 5 years. |

| Cost | Initially higher cost due to specialized equipment and ink | Lower initial cost, but ongoing expenses for maintenance and consumables may add up |

| Application | Suitable for high-speed printing and full color printing designs | Suitable for simple to multi color printing methods |

This table provides a basic comparison between UV ink and traditional ink based on various aspects such as curing process, drying time, substrate compatibility, durability, environmental impact, cost, and application.

Jettable adhesion promoters in UV printing

A jettable adhesion promoter is a special type of primer that is applied by printing it on a surface, unlike traditional wipe-on or spray-on primers. UV light is used to dry these primers, similar to UV ink. Once applied, UV jettable adhesion promoters enhance the adhesion properties of a surface, allowing UV ink to stick to the material.

UV printers require an extra print head to use these adhesion promoters. Additionally, they are sustainable, use less energy, have no VOCs, and reduce waste. While these primers are costly to implement, in the long run, they offer many environmental benefits and cost savings. Read more about the benefits of jettable adhesion promoters.

Challenges and Considerations

While UV printing offers significant environmental benefits, there are a couple of considerations to keep in mind. One challenge is the proper disposal of UV ink, as some formulations may require special handling. Responsible waste management practices are crucial to ensuring the eco-friendly advantages of UV printing are not compromised.

Additionally, the initial investment required for UV printing technology can be a hurdle for some businesses. While the long-term benefits are evident, such as energy savings and reduced waste, organizations need to carefully assess how the upfront costs align with their sustainability goals.

FAQ’s

Q: Is UV printing more eco-friendly than traditional printing methods?

UV printing is generally considered more eco-friendly due to reduced emissions, energy efficiency, and minimal waste production compared to some traditional methods.

Is it possible to make traditional inks more environmentally friendly?

Yes, eco-friendly alternatives like water-based and soy-based inks are available in traditional printing.

Q: What role do adhesion promoters play in UV printing, and are they environmentally safe?

Adhesion promoters in UV printing enhance ink adherence; jettable adhesion promoters contribute to sustainability by reducing the need for extra chemicals.

Q: How can businesses ensure responsible disposal of UV ink and waste?

Businesses can follow guidelines, explore recycling options, and stay informed about regulations to ensure responsible disposal of UV ink and waste.

Q: Is recycled paper a more sustainable choice for printing?

Yes, using recycled paper is generally more sustainable as it reduces the demand for new raw materials and promotes the recycling loop.

Conclusion

There are very many benefits of UV printing. UV printing is kind to the plant compared to traditional analog printing methods. With its UV ink and digital primers, this printing process helps the decorating industry reduce the harmful VOCs in the air, uses less energy, and creates less waste. While there are a few challenges, like proper ink disposal and initial costs, the long-term benefits for both the environment and efficiency make it a smart and green choice.

Want to learn more about UV printing, contact us today or visit our support hub.