INK FOR PLASTIC, METAL, RUBBER

BX Series pad printing ink is a high-gloss, easy-to-use, all-purpose 1- or 2-component pad printing ink for printing many materials, including plastics, TPE (TPR), metals, carbon fiber, and more. This humidity-resistant and fast-drying ink adheres to a wide range of materials. Some of these materials include ABS, rPETE, PET, pre-treated polyethylene, and polypropylene.

When used as a two-component ink, the BX series offers exceptional scratch and abrasion resistance. This enables the BX series to not only pass adhesion resistance but also withstand sterilizing chemicals such as alcohol.

The BX Series pad printing ink is available in 12 opaque colors and 2 metallic shades. All the 12-high-opacity colors are intermixable to create new shades. Contact us for the color formulation calculator; it has over 1600 PMS colors.

Compliance and ink formulation

The BX series inks have a non-toxic classification. In addition, the BX series inks contain heavy metal-free pigments and exhibit fade resistance. These features make this ink perfect for printing on food containers, toys, gift materials, industrial products, and industrial power tools.

This is an excellent ink for pad printing on pens, injection-molded parts, containers, medical devices, wood, and electrical housings. Lastly, check the safety data sheets and the product label for warnings.

Some of the key features of this ink series include:

- Exceptional adhesion properties (excellent scratch and abrasion resistance),

- Low, sweet smell,

- Fast drying,

- Water, humidity, and weather resistance

- Excellent printability and definition (very smooth and excellent release from silicone pad printing pads),

- Non-toxic—perfect for food, toys, medical, and packaging applications.

Ink mixing instructions

There are several pad printing supplies required to use the BX pad printing ink. This is the i-300x pad printing hardener and solvent. There are several solvents available for this ink series. These are BXF (fast), BXM (medium), TMG (medium), TMF (medium), BXS (slow), and BXR (retarder).

Therefore, it is important to choose the right solvent to match your application and printing environment. BXM and TMF are the most popular solvents.

As a single component, simply add 10%–20% of the appropriate thinner before printing.

To use the ink as a 2-component ink, add 10% of the hardener and mix the ink. Next, add 10%–20% of the solvent to the ink and hardener mixture and mix. Visit our YouTube channel to learn how to mix pad printing inks.

Drying the inks

Printed products with the BX series will air dry for 10–15 minutes. For hot air oven drying, the prints will dry in 1-2 minutes and a few seconds with IR heat. After thermal drying, the inks will achieve full cure within 24 hours.

*Test for adhesion 24 hours after printing.

Other products that you might be interested in: Screen printing inks and SE Silicone inks for rubber.

REQUEST INFORMATION

PMS COLOR CALCULATOR

REQUEST A QUOTE

Stay Updated with Boston Industrial Solutions, Inc. News

ADDITIVES AND RELATED PRODUCTS

Pad printing inks for any application from Boston Industrial Solutions, Inc. are made with safety and sustainability in mind. Our top-quality inks are available in single- and two-component types. We make silicone, UV-curable, and solvent-based printing inks following strict quality management standards.

i-300X Hardener

Print for unmatched durability with our uniquely formulated inks that can work for glass, nitrile, silicone, and other substrates. Unlike other ink companies in the USA, we create them on our own and perform safety and compliance testing here in Boston, so you don’t have to.

TMF Pad printing solvent

Do you rely on tampography for decorating your products? Pads, hardeners, and ink cups are pivotal in facilitating the effective transfer of images from the plate to the object and ensuring each item you produce is a hallmark of excellence.

COLORS

Pad printing inks for any application from Boston Industrial Solutions, Inc. are made with safety and sustainability in mind. Our top-quality inks are available in single- and two-component types. We make silicone, UV-curable, and solvent-based printing inks following strict quality management standards.

HD Ink colors

Pad printing inks for any application from Boston Industrial Solutions, Inc. are made with safety and sustainability in mind. Our top-quality inks are available in single- and two-component types. We make silicone, UV-curable, and solvent-based printing inks following strict quality management standards.

370

310

300

314

315

322

352

353

358

348

346

345

333

336

337

335

331

330

354

341

363

371

377

Metallic Ink colors

Pad printing inks for any application from Boston Industrial Solutions, Inc. are made with safety and sustainability in mind. Our top-quality inks are available in single- and two-component types. We make silicone, UV-curable, and solvent-based printing inks following strict quality management standards.

Mixing Ink colors

Pad printing inks for any application from Boston Industrial Solutions, Inc. are made with safety and sustainability in mind. Our top-quality inks are available in single- and two-component types. We make silicone, UV-curable, and solvent-based printing inks following strict quality management standards.

370

310

300

314

318

322

352

353

358

348

346

345

Ink Color Formulation Calculator

TECH SPECS

Pad printing inks for any application from Boston Industrial Solutions, Inc. are made with safety and sustainability in mind. Our top-quality inks are available in single- and two-component types. We make silicone, UV-curable, and solvent-based printing inks following strict quality management standards.

Medical Grade Class VI Certified

This silicone ink has medical Class VI certification and meets the requirements of the GLP Class VI Test (USP). It also meets the current FDA 21 CFR, Part 58 GLP technical requirements. This enables you to easily mark silicone components that operate under demanding conditions

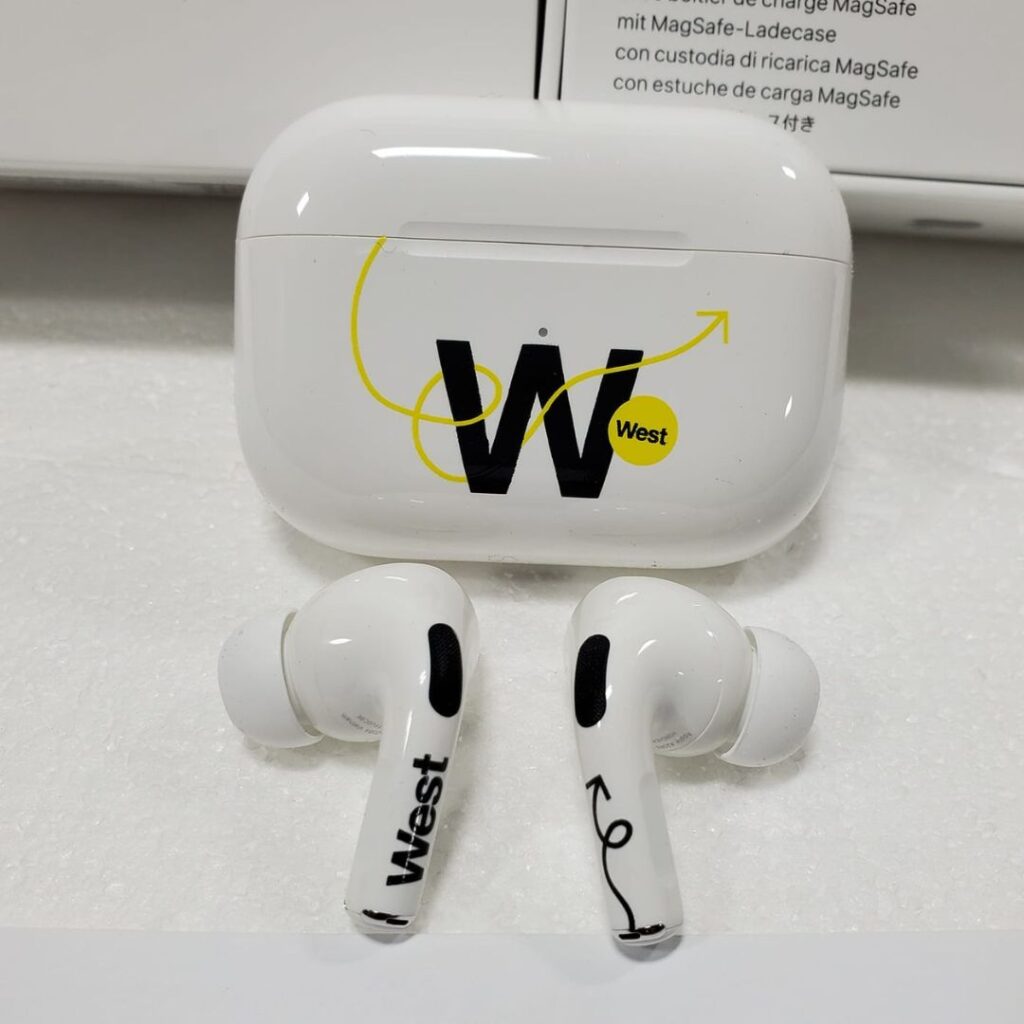

HD prints

The nontoxic, triple-milled, fade-resistant pigmentation delivers stunning HD prints.

SUBSTRATES

From our award-winning cylindrical inkjet printer and flatbeds to our pad printing equipment and lasers, Boston Industrial Solutions is

the top choice for printing experts in all industries. See how some of our customers utilize our equipment!

PP

HDPE

Ceramics

Acrylic

PP

HDPE

Ceramics

Acrylic

Check out pad printing applications

DOCUMENTS

From our award-winning cylindrical inkjet printer and flatbeds to our pad printing equipment and lasers, Boston Industrial Solutions is the top choice for printing experts in all industries. See how some of our customers utilize our equipment!

CERTIFICATIONS

From our award-winning cylindrical inkjet printer and flatbeds to our pad printing equipment and lasers, Boston edustrial Solutions is the top choice for printing experts in all industries. See how some of our customers utilize our equipment!

SUSTAINABILITY

From our award-winning cylindrical inkjet printer and flatbeds to our pad printing equipment and lasers, Boston Industrial Solutions is the top choice for printing experts in all industries. See how some of our customers utilize our equipment!

TP Series and the enviroment

- Alogens

- Aromatic hydrocarbons

- Bisphenol A (BPA)

- Formaldehyde

- Latex

- PAH

- Phthalates

- Animal origin ingredients

- Azo dyes

- Cyclohexanone

- G-B ester

- Melamine

- Persistent organic pollutants

FREQUENTLY ASKED QUESTIONS

From our award-winning cylindrical inkjet printer and flatbeds to our pad printing equipment and lasers, Boston Industrial Solutions is the top choice for printing experts in all industries. See how some of our customers utilize our equipment!

From our award-winning cylindrical inkjet printer and flatbeds to our pad printing equipment and lasers, Boston Industrial Solutions is the top choice for printing experts in all industries. See how some of our customers utilize our equipment!

From our award-winning cylindrical inkjet printer and flatbeds to our pad printing equipment and lasers, Boston Industrial Solutions is the top choice for printing experts in all industries. See how some of our customers utilize our equipment!

Still have questions? We can help

Follow us around the world as we demonstrate our latest

and greatest products on different applications.

Contact us

MORE INFORMATION

REQUEST A QUOTE