Pad printing pad FAQs

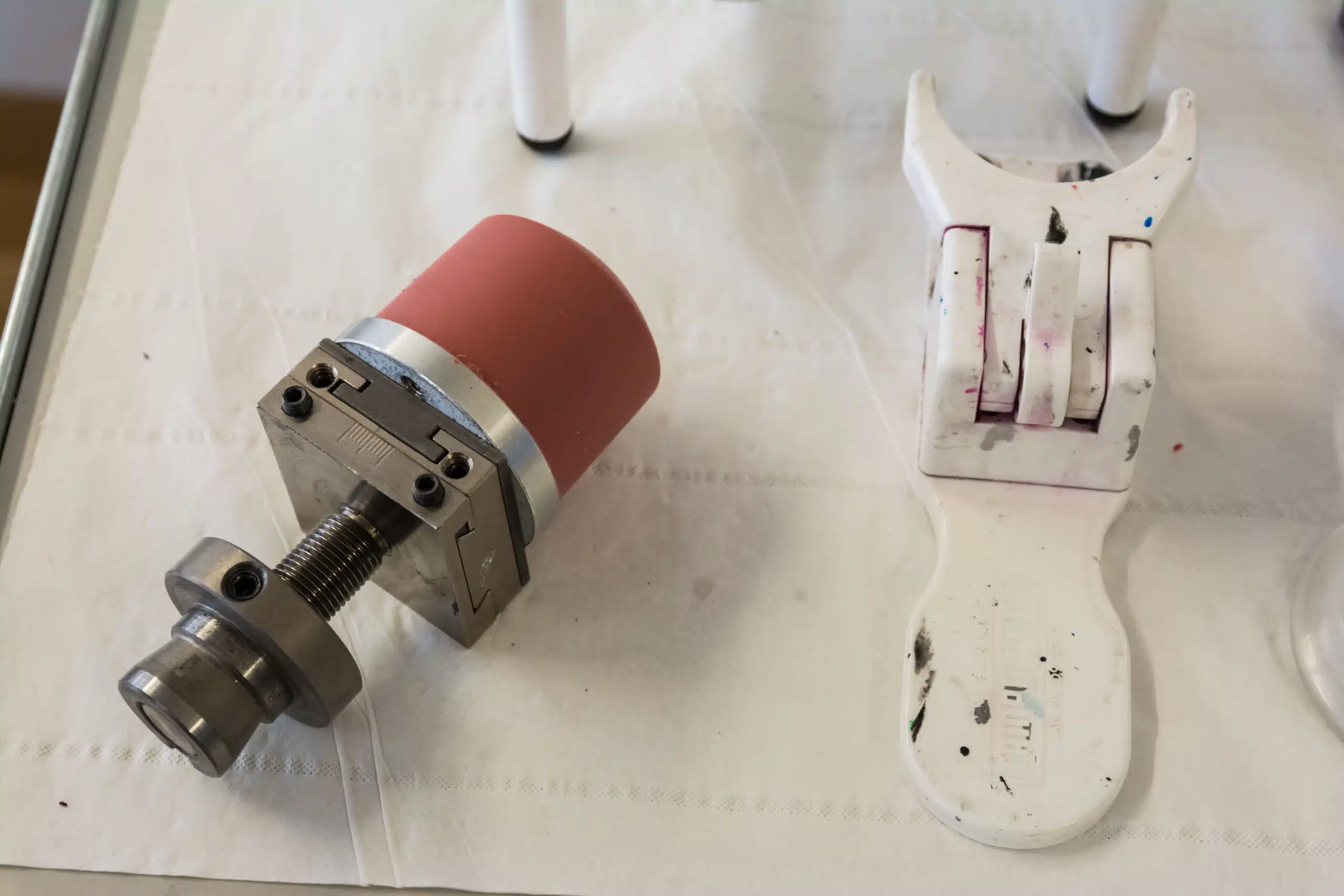

Lets review Pad printing pad FAQs. What is a pad printing pad? A pad printing pad, also known as a “pad” or “silicone pad printing pad,” is a critical pad printing supply made with silicone rubber material. Pads are used for transferring images from a printing plate (cliché) onto a non-flat surface (3D object) using a pad printing machine. Examples of 3D objects include sporting goods (golf balls), promotional products, electronic components, and more. Want to print on glass, check out our pad printing ink for glass.

What are the functions of a pad? A pad printing pad has several functions, including:

- Ink transfer: the pad picks up ink from the etch and transfers it to the object.

- Pad printing ink release—after ink pick-up, the machine moves the pad and presses it against the substrate, releasing the ink on the surface of the object.

- Repetition and consistency—the pad printing process is a very repetitive process. Because the pads are made with silicone, they maintain print quality even after thousands of printing impressions.

- Crisp images—the pad’s surface helps ensure that the printed image is sharp even on tough-to-print surfaces.

How are pads made? Pads are made from a mixture of LSR, oil, and a catalyst. Once this mixture is degassed, the mix is poured into molds that take the shape of the desired pad. After the silicone cures, a base made of wood or aluminum metal is attached to the pad using a silicone adhesive. Learn more about the best silicone ink in the world.

Pad printing pad usage

What is the useful lifespan of pad printing pads? It is possible for pads to last for thousands of impressions (50,000–100,000). However, the exact useful life of pads can vary greatly from one application to another. Some of the factors affecting pad durability include the silicone pad material, pad printing ink type, pressure, maintenance, and care. We recommend that you always monitor the condition of your pads and replace them when they no longer produce high-quality prints or show aging signs.

What is the best pad for my application? When choosing a pad for your application, it is important to make sure that the pad is at least 20% larger than the image. Additionally, you should make sure the part fits the pad printing machine and part size.

Cleaning and storing silicone pads

What is the best way to clean a printing pad? Another of the Pad printing pad FAQs is the best way to clean a pad. The best way to remove dry ink and debris from the pad surface is to use regular clear packaging tape. Also, a soft, lint-free cloth soaked with mild ink solvent will remove the ink from the pad. Before any printing job, always clean the pad before starting a pad printing job.

How should I store my printing pads? Store pad printing pads in the upright position on their base. The pads should not touch each other to prevent dimples or creases on the pad surface. Lastly, store the pads in a cool, dust-free environment away from direct sunlight.

Can I extend the pad’s useful life? Yes, you can extend the pad life using pad oil. Wiping this oil onto the pad increases the pad’s useful life. Additionally, having two pads that you alternate from one job to another will help increase the pad file. When a pad “rests”, it restores the uncompressed silicone state.

How do I prevent pad wear? A pad wearing out is part of the pad printing process. However, using the right pad and tooling fixtures will help eliminate pad wear. Wrong pad and tooling are a major cause of image distortion.